Misdiagnosis: Convair Crash at Wonderboom (part 2)

Last week, we went through the flight and crash of a Convair 340/440 at Wonderboom Airport in Pretoria. As a quick recap, as the Convair rotated the left engine caught fire. The flight crew declared an emergency but they lost control of the aircraft while still turning back as the fire melted through the aileron cables. The aircraft crashed through a factory building and impacted the ground on the other side.

The engineer responsible for the maintenance of the aircraft, who was sitting on the jump seat with the flight crew, was killed in the crash. The flight crew, two of the passengers and four people on the ground were seriously injured.

Last week we looked at the issues on the flight deck and that the flight crew did not appropriately react to the fire that they knew was burning in one of their engines. It is easy to wonder why they disregarded the checklists and did not make any attempt to extinguish the fire, which rapidly burned through control cables making it impossible for them to fly the aircraft. However, we also need to remember that the flight crew is often blamed for their errors because they are the last line of defence when things go wrong. Sure, we expect competence from commercial pilots but also they are in the one position where simple mistakes can’t be forgiven. A simple error on the apron or in the hangar may not feel like it has such overwhelming consequences but the truth is, it is just as much a part of the chain of events leading to the crash as the flight crew’s mistakes.

So although there are a lot of questions that can be asked about the flight crew’s response, there’s a key issue that we have to not lose sight of: an engine should not burst into flames on take-off.

When the investigators arrived on the scene, they first determined that fuel and oil were all as expected. The right engine had been operating normally up to the moment of impact. They focused on the left engine as the passengers clearly reported that they’d seen flames as the aircraft rotated.

The left-hand engine was located just behind the fuselage at grid station J25. The engine exhibited fire damage signatures near the carburettor. The accessory gearbox had broken off from the housing assembly. The left three-bladed propeller had broken off from the gearbox and was located at grid station K25. The first blade was missing, the second blade had disintegrated from the mid-section,while the third blade was fairly intact. The damage observed on the propeller blades was indicative of damage caused during the running of a low-powered engine. The exhaust tubes were still secured on the centre section of the wing. The exhaust exhibited damage caused by an in-flight fire and had signatures of overheating and discolouration.

That doesn’t really tell us a lot other than confirm what the passengers had already reported: the engine was on fire but still running when the aircraft crashed.

But when the investigators disassembled the engine, they found something much more damning: the pistons in cylinder 7 and 13 were damaged and in a way that had nothing to do with the impact.

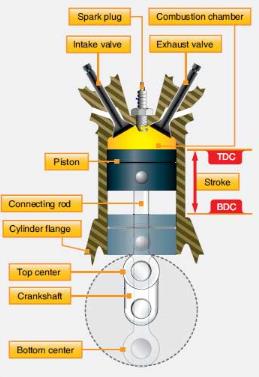

Now I’m not going to pretend I know the intricacies of how an engine works (although I know there’s a few people in the comments who could break this down!) but the report makes it clear that for efficient operation, there are three requirements.

- The piston rings must be in good condition in order to provide maximum sealing during the stroke of the piston. There shouldn’t be any leakage between the piston and the walls of the combustion chamber.

- The intake and exhaust valves need to close tightly so that there is no loss of compression.

- The opening and closing of the valves must be such that the highest efficiency is obtained when the engine is operating its normal-rated RPM.

The compression rings and oil ring packs of piston No 13 were clearly damaged, with hard carbon deposits which had built up over time on the piston crown. This damage showed that cylinder No 13 had not been operating efficiently for some time, which had reduced the power available to the left engine.

More importantly, though, the exhaust valve head of piston no 7 had fractured before the impact. This must have happened during the take-off roll. The fracture caused a backfire and led to the left engine manifold pressure dropping, which the Pilot Monitoring had specifically called out shortly before he called V1.

This backfire would have caused the initial flames that the passengers in the cabin reported at the engine cowl flaps above the cowling.

Having learned what they could from the engine, the investigation’s attention shifted to the Convair’s maintenance, which had been done by a local Aircraft Maintenance Organisation (AMO). And there, they found a rather convoluted story.

The Aircraft Maintenance Organisation had been audited by the South African Civil Aviation Authority (SACAA) the year before the accident, in September 2017, specifically to determine whether they could be authorised to offer full maintenance to Convair 340/440 aircraft.

The SACAA did not authorise the maintenance company for full maintenance for the aircraft, as the company did not have adequate facilities for the maintenance activities and it did not have a training programme for certifying personnel on the Convair 340/440, which was required. The maintenance company was rated for category B (structural repairs and spray painting) only.

The maintenance company then submitted paperwork to show that a hangar agreement was in place which would extend their facilities. They also submitted paperwork to show that they had a licensed maintenance engineer and that he was the only maintenance engineer in South Africa licensed for the Convair 340/440 aircraft. There was literally no one else in the country who could do it.

The SACAA accepted this new submission and issued the maintenance company with A and C ratings, which allowed them to offer line maintenance on the Convair 340/440 aircraft.

On the 18th of June, less than a month before the accident, the maintenance company sent another letter to the SACAA requesting approval to be upgraded to full maintenance on the Convair 340/440. They attached the dimensions of the hangar as evidence that they could accommodate the aircraft for maintenance. On the 22nd of June, the maintenance company was granted one-time authorisation to carry out full maintenance and release of the Convair 340/440 to service, even though the maintenance company had still not addressed the issue with the training programme which had been highlighted in the original audit. This one-off authorisation did not include a validity period.

So the Aircraft Maintenance Organisation, having failed the audit, was subsequently authorised to do full maintenance on the Convair 340/440 as a one-time thing, which seems to have been swayed by the logic that there was no one else that could do it.

The thing is, the maintenance company still had only the one maintenance engineer for the Convair 340/440, the only person in the country who was licensed to do the work. This means that there was no one available to inspect the maintenance once it was done.

The engineer who performed the maintenance was also in charge of inspecting his own work.

The AMO had limited resources in respect of maintenance personnel to properly maintain the Convair 340/440 aircraft as it only had one licensed Aircraft Maintenance Engineer (LAME) who was responsible for the full maintenance including the last A, B and C maintenance checks carried out on the aircraft four days prior to the accident flight. Therefore, all duplicate inspection task(s) required in terms of Civil Aviation Regulation Part 43.04.8 were carried out by the same licensed AME according to the maintenance records provided to the investigation team. There were no records which suggested that the organisation had contracted an AME who was rated on a Convair 340/440 or any person meeting the requirements of CAR Part 43.04.8 for the purpose of duplicate inspections. This was in contravention of Civil Aviation Regulation Part 43.04.8.

This was, of course, that same engineer in the jump seat on the flight.

The damage to the cylinders showed that the left engine had not been operating efficiently for some time. How was it that he hadn’t noticed?

In February, five months before the accident, the left engine manifold pressure gauge had been reported as defective. At the time, the maintenance engineer removed the gauge, cleaned it up, signed it off and refitted it to the aircraft.

Then on the 5th of May, just over two months before the accident, the same defect was reported again. Again, the engineer removed the pressure gauge, cleaned it, signed it off and refitted it to the aircraft. Job done.

There was nothing wrong with the gauge. The left engine manifold pressure was low because of the damage to cylinders No 7 and No 13.

With no one else to question his decision or check his work, the engineer misdiagnosed the problem, not once but twice, both times removing the gauge and cleaning it before installing it again. It’s blatant that he never looked at the cylinders, where the carbon deposits would have made it clear. He also obviously never did the required compression tests, which would have shown the damage to the compression rings. A simple short cut that usually didn’t much matter, as long as everything was OK. A lot like not bothering with the checklist when you think you know what to do anyway.

The Convair 340/440 continued to fly with the damaged cylinders.

That day, as the Convair engines worked to provide the thrust to reach take-off speed, the faulty No 7 cylinder exhaust valve head fractured under the pressure.

Once that exhaust valve failed, the cooling fins overheated. The heat burned a hole through the housing, leading to the flames that the passengers saw licking the exhaust and the cowling.

With the engine at high RPM, the fire quickly began to weaken the front wing spar. The mounting rivets melted in the heat, releasing the aileron pulley attachments. The pulleys fell apart in the wing, slacking the aileron control cables, forcing the aircraft to roll to the left and then crash.

This is a clear illustraion of the “holes in the cheese lining up”, a quick way of saying that every opportunity to avoid this crash had failed.

If the carbon build up and the damage to the cylinders had been recognised, the cylinders could easily have been replaced. If the maintenance and inspections had been done according to regulation, then the misdiagnosis of the pressure gauge might have been caught. If the crew had aborted take-off at 50 knots, when the manifold pressure dropped, the fire would have been easily dealt with on the ground. If they had followed their checklist and secured the left engine immediately, the fire may have been arrested before the aileron control cables had failed.

Instead, the SACAA approved a maintenance organisation to offer maintenance on the Convair 340/440 even though there was no one available to inspect the work done. The Convair was repaired by the only licensed engineer in the country who twice misdiagnosed the fault. The aircraft was piloted by two pilots who hadn’t bother to apply for the validation to fly the Convair 340/440 in South Africa; however they were experienced and realistically, they were both perfectly qualified to fly the aircraft, the missing rating was simply a paperwork issue.

That’s not to dismiss their mistakes: they didn’t abort the take-off to find out what was wrong with the left engine manifold pressure and they didn’t prioritise extinguishing the fire once it was clear that the left engine was burning. But let’s also remember that they didn’t cause the engine failure and fire in the first place.

In my opinion, the report is a bit spotty and not very good at offering a linear version of events but it does try to break down these issues rather than focus slowly on the final seconds of the flight.

Probable Cause

During take-off, the left engine caught fire and the crew continued with the flight without securing the left engine as prescribed in the aircraft flight manual (AFM). The crew declared an emergency and attempted to return to the aerodrome, however, they lost control of the aircraft and collided with power lines prior to crashing into a factory building.

This is an executive summary of the final sequence of events. I think what they are trying to say here is that the probable cause was a fire in the left engine.

**Contributory Factors**

3.4.1 Pre-existing damage to the cylinder No 13 piston and ring pack deformation and, most probably, the cylinder No 7’s fractured exhaust valve head that were not detected during maintenance of the aircraft.

3.4.2 Substandard maintenance for failing to conduct compression tests on all cylinders during the scheduled maintenance prior to the accident.

3.4.3 Misdiagnosis of the left engine manifold pressure defect as it was reported twice prior to the accident.

3.4.4 The crew not aborting take-off at 50kts prior to reaching V1; manifold pressure fluctuation was observed by the crew at 50kts and that should have resulted in an aborted take-off.

3.4.6 Lack of crew resource management; this was evident as the crew ignored using the emergency checklist to respond to the in-flight left engine fire.

3.4.7 Lack of recency training for both the PF and PM, as well as the LAME.

3.4.8 Non-compliance to Civil Aviation Regulations by both the crew and the maintenance organisation.

The report concludes with five recommendations, which pretty much come down to that the aviation authority needs to pay more attention. They recommend that the other aircraft maintained by the maintenance organisation should all be checked, which is sensible as their systems for checks and balances clearly is out of whack. But also, that the aviation authority needs to look at the effectiveness of its Part 91 operations, as it is the aviation authority, after all, who relented and agreed for the maintenance organisation to take responsibility for the Convair’s maintenance, although they clearly didn’t have the staff or the processes in place.

The engineer clearly made a mistake, one that he paid for with his life. When it comes to it, though, the lack of oversight absolutely was a contributing factor, allowing all of those involved to get away with a lax and unregulated approach to a passenger flight which should have been a wonderful day out in a historic aircraft.

In a nutshell. Have a look at avcom.co.za for the take of the local aviation community. You may have to register for “academy and flight safety” forum but it will be worth the hassle.

Regards

Lee Brand

Johannesburg, SA.

Well, the thick plottens! Sylvia cleverly kept the last bit for another week.

There have been accidents that resulted from in themselves relatively minor events that formed a chain leading to the eventual catastrophe.

Not here, this is a litany of a string or better: a tapestry of events, each totally avoidable, all due to blatant ignorance. Each one preventable until the final one: failure of basic airmanship by the cockpit crew who had not one, but two last-minute chances to bring the saga under control and walk away from it: One, no reaction to an evident meachanical problem before V1 where they still could have brought the aicraft to a stop, and two: no attempt whatsoever to shut down the failing and burning engine. Not even the very basics, let alone the proper procedures according to the “memory items” and emergency checklist – which seemed not even to have been ready for immediate consultation.

Of course the procedures surrounding the maintenance of this aircraft left something, quite a lot actually, to be desired and that also includes the overseeing authorities. All those are guilty and should, at a minimum, be sacked.

But that still does not absolve the crew who untimately accepted responsibility for an aircraft that they were in fact not even qualified to fly. Without properly checking and testing it before accepting passengers. I have flown with Australian pilots and all were highly professional. And the crew operating this aircraft – at least the PIC, were in the “highly qualified” category – highly qualified, but not on this kind of operation as the sequence of events amply demonstrated

So how come they decided to embark on this highly UNprofessional, even illegal flight, in a typical “cowboy” way of operating this aircraft, is a mystery.

“Kick the tyres, light the fires”.

I suppose all the guilty parties, including regulators, wanted to do everything in their power to help this beautiful airplane make its flight to the museum. If I’m correct it would be another example of “get-there-itis” that affects even the best.

Hat_eater: That may be an explanation; however, it is no excuse!

This is truly a shame. A lot of things were handled improperly by several people involved and it’s hardly surprising that there was an accident.

I’ll jump on my personal soapbox; airplanes have to be taken seriously 100% of the time. Even when the purpose of the flight is recreational, it’s still a deadly serious business. My guess is that somehow, several of the people involved just didn’t take this airplane or this flight all that seriously.

I am a minimally competent back-yard auto mechanic, mostly on older cars. Confronted with the readings from the manifold pressure gauge, even I would first look deeper than the gauge! (The gauge!!! The LAST thing you look at!!) A compression test, which would have been my first move, would have revealed the problem instantly.

You don’t need to be a specialized aircraft mechanic to know this. It doesn’t need to be an airplane. This is basic Internal Combustion Engine 101, and it applies to anything with pistons. I’m sorry this guy got killed, no one deserves that, but incompetence as a mechanic often does carry this penalty, regardless of what kind of engine we’re talking about.

“ncompetence as a mechanic often does carry this penalty”. It’s my impression that mechanics rarely fly on aircraft they’ve maintained; they have other aircraft to maintain.

I see Sylvia cites the huge experience of the two pilots. A comment on the previous article suggests that this was almost entirely in modern airliners, which are more complex in some areas (e.g., spoilers and multiple sets of flaps, sheer size) than 70-year-old planes — but their engines are so reliable that twinjets routinely fly across the Atlantic. I wonder how recent their experience was with piston engines, and whether they’d had any of the sort of simulated-emergency training that I understand they’d have periodically gotten for their jobs — my guess is not, as simulators for big old piston planes wouldn’t get a lot of use.

I’ve been in the cockpit of an Aussie passenger jet in the air — 30+ years ago they allowed that on some of the less-busy routes — and certainly didn’t see anything sloppy or unprofessional. I think Rudy has sense of it — they really didn’t think this plane could possibly be as hard to handle as their day jobs.

It is customary that an aircraft mechanic can be requested to ride along on any aircraft they have repaired. It doesn’t happen often, but the idea is that if the pilot is not confident that the repair actually solved the problem, they can challenge the mechanic to ride along and if the mechanic refuses, that is tantamount to admitting they don’t trust their own work.

In a less challenging manner, pilots have been known to ask a mechanic to ride along as a way to demonstrate a problem. I’ve actually experienced this myself, although I suspect that the motive may have been somewhat personal; this pilot had been trying to gain my romantic attentions and the fact that I was married didn’t seem to impress her.

That having been said, however, you are completely correct in saying that most of the time, the mechanic/engineer is probably busy dealing with the next squawk and doesn’t look back once the job is signed off, unless there’s a good reason to do so. Signing off a repair requires that one evaluate their actions and to be certain that the job is done correctly and IAW all applicable requirements. Most repairs are routine. When I worked for a flight school, maintaining mostly 100 series Cessnas, I performed the same handful of repairs over and over again, with a handful of exceptions. Mostly it was minor squawks and 100 hour inspections. I did a lot of brake re-lines because student pilots tend to be hard on brakes. Likewise, changing the main gear tires was a common task.

The majority of our work was simple and repetitive, but that’s not to say that it wasn’t important. Leak down tests on cylinders were important and took relatively little time to perform. Ignoring excessive leakage in any cylinder strikes me as foolhardy, at best. I can only surmise that the engineer probably did not perform such a test, thinking that the plane was headed to a museum soon and it wouldn’t matter. There is an extreme, tragic, irony that he lost his life because of this.

Everything about this crash shouts out to me that the crew and the engineer did not see this flight (or this aircraft) as being much more than an historic curiosity and forgot that even toothless old airplanes can still bite hard. Every aircraft, from the simplest to the most complex, flies because of the efforts of many people: the design engineers, the builders, the rest pilots, etc. etc. Even a J3 Cub deserves a lot of respect. More to the point, failing to adequately respect any aircraft can be lethal.

Mark Sorensen makes a point. In the ‘seventies I was a member of the Tiger Club, then based at Redhill. The club aircraft had a sticker on the instrument panel that said: “All aircraft bite fools “.

And Chip has a point too, when he writes “… they really didn’t think this plane could possibly be as hard to handle as their day jobs.” I agree, but it still does not explain why nobody, nobodyat all who was involved, from the authorities down to the maintenance base, the mechanic and the flight crew, even bothered to do a proper check. The authorities issued a licence to the AMO in spite of near-overwhelming indications that this organisation was in no way fit to maintain nor to carry out major repairs to this aircraft, without anyone licensed to supervise the mechanic. The mechanic who had the licence to work on the CV340, but failed to spot even basic mechanical faults (see Susan’s comments, she certainly knows her “stuff”) and instead kept “repairing” a gauge that probably was in good working order, down to the pilots who broke if not every, certainly many rules in the book and failed totally in maintaining even a veneer of professional airmanship.

A lot of issues here that seem at odds with what can be expected from even a PPL with only a few hours under his or her belt.

How many minutes from time of T/O to crash?

Any one knows?

Had the same scenario happen to us also on a CV 340 taking off from 6500 PA, engine fire during gear retraction with maybe 70% power loss on that Eng.

We climbed to about 700 feet AGL and thank God it feathered and fire extinguished.

Maybe 3 – min with fire. I knew the aircraft would not climb had we feathered before.

Turning final towards the dead engine due to terrain, flaps on the lower wing did not come out! Just the upper wing ones.

Retracted that on and we regained roll control and made it to the runway.

Probably my worst Eng failure case.

Lost many on the DC6. One also during gear retraction.

Have not lost one more for the past 28 years, no more radials flying, just once in a while a Stearman and son a DH2 Beaver!!! Yeah!

I once was getting an aircraft out for flight and the engine wouldn’t start. Our “qualified” aircraft mechanic’s first thought was to get a hammer to give the starter motor a whack assuming it was a sticking bendix (pinion). Fortunately we found the cause in a fractured battery cable connector before he did any damage!

Not all qualified so called “engineers” are worthy of their titles!

When I read the original report, my first thought was that this was a right royal shambles. No-one comes through very well (I think I am being polite here) except for the emergency services. Sylvia’s analysis is spot on and highly readable. Thanks for taking the time do such a great post. The comments say it all, too. For me, historic aircraft are a joy so this is all such a tragedy. Still nothing though on the Netherlands link though.

Manuel, I think that some “aviation buffs” would like to read some more of your stories. An engine failure at 6500 PA would have been a handful, performance would have been affected subsfantially. The DC6 was a beautiful machine, but the radials in the ‘fifties and ‘sixties had become very complex and engine failures were not uncommon. In some of my old boyhood aviation books stories abound about those aircraft, fortunately with four engines, that would come home on three. Not quite routinely, but not infrequently either. If you have first-hand erxperience, Manuel: Tell us more please! I am sure that Sylvia will accommodate you.

Thanks a lot for the interest Rudy.

Indeed, there is no question in my mind, had I somehow continued till now on the DC-3, 6 and CV340 I would be dead by now.

No matter how much you cared for those engines, they failed quite a bit.

Matter of time till failures compound too much or we end up making a crucial mistake and tragedy happens.

Do not know how only one flap extended on the case I posted, guess there must have been a Split flap protection that did not work and allowed that to happen but to our great luck if there was one I am very glad it did not prevent us from retracting the extending one and recover from the roll over.

Do not recall what the engine damage/fire destroyed on its flap side to disable its operation.

Good thing we still had descend angle to allow us for gear extensión on short final.

They just gave us another CV-340 and off we went again.

All in all I feathered 1 Eng. on the DC-3, 2 on the CV-340 and maybe a dozen on the DC-6. Maybe 9 years on those?

Shut down one Eng. on a BAC 111 and two on the 727, all because of oil leaks. One after maintenance in Miami.

1989 we started flying 737´s, 1998 came the Airbus 320 family and voila, till retirement almost two years ago up to date no more Eng. shut downs.

Total hours by now some 38,000.

Ahhhh, interesting story on the 737-300.

Cruise, oil quantity started coming down on one Eng. and it looked real. Got very very slowly all the way to zero.

Ok lets see what happens to the oil temp and oil pressure, we will shut it down if needed.

Time of descend, thrust back, some minutes later hey! Oil Qty rising!! ?? Wow Come on!?

Landing, normal Qty!!

Mechanics could not find anything wrong in Miami. Hmmmm

Returne flight was pretty much the same.

They took the Eng Off here, found something wrong with the scavenge pumps.

Oil was staying some place in the Eng. and not returning well to the tank they told me.

Now I fly my beloved Cessna 180 and a Learjet 75.

Stay safe.

Brgds.

Manuel

Noticed I mentioned ¨here¨ some place in my post. Sorry.

My home town is Guatemala in Central America. Main airport MGGT.

Well Manuel. You certainly did have your share of engine trouble. I had to shut down an engine in-flight twice, both on the old Fokker F27.

The first time on a flight from Spain to Paris. My copilot was looking outside and wondered what the town was we were flying over. “Bordeaux”, I replied. “I have never been there”. “Well, you will now”. The oil pressure on one engine was dropping and the red warning came on.

So we shut it down and diverted. It was a non-event. My copilot was the handling pilot, I saw no reason to take over, we had practiced it over and over in the simulator. Actually easier on the real aircraft. An accessory had been working itself loose from the casing and allowed oild to escape through the gap.

The second time we came, I think, from Scandinavia and had to deivert to Brussels. Different copilot, this time I was flying. Same result: aircraft was fixed and the next day we continued.

Unfortunately I cannot afford to keep flying, too expensive in Europe. So I went to university and in two weeks time I will be conferred with my masgters degree in history.

Great subject and when you fail the course, you will be history.

Seriously though: ask Sylvia to post some of your adventures.

Hmmm, oil leaks also what you had. Ineteresting Rudy.

Glad all went fine.

Hope you find a way to stay up in the sky!

Silvia would have to work too much editing my forgotten stories but I will be here learning. Looks like a great site.

Best regars to all.

Just for the record, Sylvia is happy to edit. :)

😃😃

That’s attitude!! 👍🏼

I am not a pilot though I am an aviation enthusiast. I would love to attain a pilot license of some type but the small pesky thing called finances can be a determinant.

I have followed (YouTube) an ATP who files as a F.O. for a major airline here in the states. If I have heard him correctly when he has detailed his flying experience-general aviation, military and certified airplane mechanic that he can only hold one type of airplane rating at a time. He currently holds the rating for 777s.

Would that hold true in Europe/Africa? IF so I am in agreement with the more experienced commentors. These pilots had no business flying this airplane even though they were “experienced pilots”.

I follow another website that covers airplane accidents-Kathryns Report.

It surprises me often that Airline Transport Rated Pilots have fatal airplane accidents flying their general aviation aircraft. I would think that the GA aircraft would be easier to fly than the Big Birds. Maybe a certain amount of complacency enters into the picture or they feel that they can be less vigilant fly their smaller planes.

QUOTE

that he can only hold one type of airplane rating at a time

Hi James,

That might be a company policy.

Don´t think the FAA has any restriction besides for one to stay current on all types.

If your dream is being an Aviator GO FOR IT!!!

Airline flying and most of general aviation flying can be quite different. Again, one has to be current on each sort of operations and be very careful.

GA operations are more of a be on your own thing.

That would make sense about a company policy about current aircraft ratings