Preliminary Details of a Helicopter Crash in New Jersey

I don’t normally write an article based on a preliminary report; however, this one made me sit back in my chair.

On the 4th of June 2022, a Bell 407GXP helicopter, registration N98ZA, crashed near Fairfield, New Jersey.

The Bell 407 is a single-engine helicopter with a four-blade “soft-in-plane” design rotor, which means that it is an articulating rotor system with a composite yoke attached to the mast. The Bell 407GXP in the accident was built in 2015 and powered by an Allison Model 250 turboshaft engine.

The helicopter was on a positioning flight from Essex County Airport (CDW) in Caldwell, New Jersey to John F. Kennedy International Airport (JFK) in New York. Only the pilot was on board; local media reported that he was travelling to New York to pick up a customer for a charter flight.

At 11:47 that morning, the helicopter departed Essex County Airport, which has an elevation of 53 metres or about 175 feet above mean sea level (amsl). The weather was clear. The pilot climbed to about 500 feet amsl and flew south-east.

About two miles south of Teterboro Airport, the pilot contacted ATC and asked for a return to Essex County. He said no when the controller asked if he needed assistance. He must not have been very concerned, as he said no when the controller asked if he needed assistance and reversed course back to Essex rather than land at Teterboro. At Essex, the pilot was cleared to land on runway 28.

The helicopter crossed the runway threshold flying at 33 knots groundspeed at 150 feet amsl (so about 25 feet over the runway). It continued at that altitude and groundspeed for about ten seconds, then slowed down as the nose pitched upwards to climb away, turning slightly to the right.

A CCTV camera at the airport showed that the nose of the helicopter yawed to the right as the helicopter slowed. Something was wrong.

In normal operation, the main rotor mast connects the transmission to the rotor assembly, rotating the upper plate and the blades using the power from the engine.

Instead, the helicopter began rotating around the main rotor mast.

An eyewitness said the Bell 407 was about 100 to 150 feet in the air when it began to spin and then crashed into the grass at the edge of the airport.

From the report:

Seconds into the vertical descent, the right yaw slowed, stopped, and the helicopter rotated to its left for the remainder of the vertical descent to ground contact. After ground contact, the main rotor continued to turn and the main rotor blades continued to strike the ground, ultimately shedding about 50 percent of the span of each blade.

Thirteen minutes had elapsed since the helicopter had taken off.

You can hear the ATC Audio after the crash on this video from FX Aviation. Note the images were added for effect and are not of the accident helicopter.

Rescuers found the pilot still in the pilot seat, partially leaning out of the cockpit. He had obviously suffered severe head injuries. The helicopter fuselage and tail boom were substantially damaged.

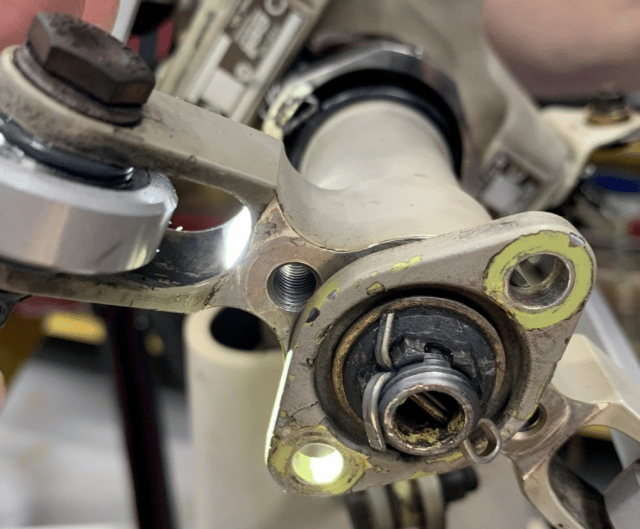

An examination of the wreckage found that the tail rotor crosshead drive plate, which should have been bolted to the tail rotor crosshead, was not attached. It should have been bolted in with two bolts. There were no bolts on the scene and no fragments found in the threading. In fact, the threads where the bolts should have been screwed in were completely undamaged: there was no trace of the bolts or any deformation or cross-threading.

The breaks on the rotor blades showed that the main rotor flight control had been connected to the cockpit controls at the time of impact. Similarly, breaks to the tail rotor gearbox and pitch control road showed that tail rotor control had still been connected to the pedals.

Moving the “pitch change push-pull tube” correctly moved the pitch change rod. When the pitch change rod moved, the attached tail rotor crosshead drive plate moved, but without moving the crosshead, which should have been attached with those two missing bolts.

The Bell 407GXP had undergone maintenance the day before, which included the installation of the tail rotor.

The director of maintenance said that before the installation, he prepared the tail rotor assembly by laying all of the parts out on a maintenance cart. He installed the tail rotor assembly and asked a mechanic to verify the mast nut torque.

It would seem that the investigators were not convinced by the director’s use of the terms “finished” and “verified”.

He then “finished” the installation and had another “verify” the work.

I’m not sure I’ve seen a report use quote marks to denote possible untruths before.

A company pilot completed a preflight inspection of the helicopter and performed “ground functional checks” and three consecutive maintenance runs to affect balancing of the tail rotor.

The director of maintenance admitted that after the mast nut torque application, he was called away to consult on other repairs, and then came back to complete the installation. He wasn’t sure how long he was away.

The NTSB is continuing the investigation under accident number ERA22FA257, with supporting staff from the FAA and from Rolls Royce, who acquired the Allison Engine Company in 1995.

Sounds like another example of that period of reduced availability / increased accidents after “maintenance”.

It is such a common root cause in not just aviation accidents, but reliability events across the whole spectrum from IT through to civil engineering.

And not following the full process + getting distracted is such a common sub-cause. “I thought I had shut the valve” / “the gun was supposed to be unloaded” / “I thought the other person was going to close the access hatches on the floating bridge before we went home for the weekend”…

Not following the proper process and checklists is just like rolling several dice – most of the time they won’t all come up 1s, sometimes they will…

Not forgetting of course the standard psychological interaction with low-probability events: it’s been fine the last ten times, it’ll be fine again.

Tail rotor held on with spit and then shook loose during the landing?

It’ll be interesting to see what kind of data recorders were onboard, the lack of these made the 2020 Calabasas crash more of a mystery than it needed to be. The mystery here is why the pilot turned back.

We won’t understand the pilot’s decisions until we know what anomalies he observed in the aircraft’s behaviour and how he interpreted them. Whatever he thought the problem was, he clearly didn’t think it was anything serious enough to require an immediate landing or declaring an emergency.

The Bell 407 GXP has Garmin G1000H “glass cockpit” avionics; I’m not certain if that includes an autopilot.

I’m guessing (as a layman) that the rudder might have felt sluggish or less responsive when flying manually; if the helicopter was going on autopilot, it might have seemed like nothing was wrong? so the pilot may not have noticed anything en-route, and only thought something was weird when he switched to manual control near Teterboro. Maybe he thought maintenance did a bad job with some adjustments, and decided to return to Caldwell and have them fix it.

The tail rotor would have generated pressure on the drive plate at high rpm. For the landing, as the main rotor torque was reduced, the tail rotor force would have diminished as well, allowing the rotor to slip.

I also wonder if using the clutch immediately and doing an autorotation landing would have helped. It’s presumably counterintuitive to do that when the engine is running fine, so I wouldn’t expect the pilot to think of doing this. But does successful autorotation require the rail rotor to still be linked to the main rotor and working?

I guess what I’m wondering is, how do you notice and identify a malfunction like this with “glass cockpit” avionics? And if you are aware, is there a way to effect a landing that you can walk away from?

P.S. There are 3 places called “Fairfield” in New Jersey.

The maintenance claims sound suspicious. If it wasn’t for that I’d suspect foul play.

Wonder why the “lockout-tagout” philosophy and protocols used by other safety sensitive professionals isn’t used in aviation maintenance

It is, depending on specific procedure and regulation framework (usually based on size of aircraft / operation) — the problem is that, all the procedure in the world doesn’t mean a thing if people don’t follow it.

Not really much to comment on, here. The lack of professional oversight and failure to adhere to established procedures is absolutely appalling.

There was “professional oversight” if the mechanic had (I suspect he does) a mechanics certificate for “airframe”. Full A&P or “IA” not needed here. Most aircraft are “returned to service” by the log entry of the mechanic who did the work, with no additional inspection.. This is true for part 121, 135, and 91 aircraft (airline, charter, and general aviation, respectively) .

Log entries for 121 operators are often done while conversing with an airline “maintenance controller” over phone, etc., but that is just someone, somewhere, talking on a phone. Not present and inspecting the work.

That work might be done by a new guy, a tired guy, a frozen guy who has been working outside at night, flashlight in mouth, with the maintenance controller pressuring him to get it done quick for the scheduled flight. He might not be real familiar with THAT aircraft, or THAT component or procedure.

THAT is often the job. Do you think mistakes are made? Yup.

Choose your mechanic with care…extra time to do a job allows more thoughtfulness and double checking.

RII (required inspection items) etc. do exist, but most repairs are not such, and the plane flies with passengers based on the say so of one person, who is hopefully trustworthy, attentive, and not at the end of 20 hours of work, which happens plenty to those who work “on call” in addition to normal hours. Common.

Same guy again, John. I felt the need to add that there are no “duty time” regulations whatsoever for mechanics. I am an a/p with IA, and also a charter pilot. A guy I flew with who was a retired airline captain (due to age..still legal for 135 charter) had no idea that this was the case. After a whole career at a major 121 carrier. Argued with me a little on it, in a friendly enough manner..I had a few 24 hr days doing contract line maintenance at a medium sized airport served by a few airlines, none of which had their own mechanics at that field. No, I’m not at my best after that. Nobody looking over your work. Then the passengers board…etc..off she goes! I feel for the guy who made this mistake on the tail rotor. And for the poor pilot, too. It could have ended worse.