Pitot Covers Left On Aircraft At Brisbane. Again.

On the 27th of May 2022, an Airbus A350-941, registered in Singapore as 9V-SHH, was being prepared for scheduled passenger flight SQ256 from Brisbane, Australia to Changi Airport, Singapore.

An engineering maintenance contractor at Brisbane providing Maintenance, Repair, and Overhaul (MRO) services was tasked with the maintenance, certification and dispatch required for the A350 during the two-hour turnaround.

Two staff were responsible for the service: a licenced aircraft maintenance engineer (LAME) and an aircraft maintenance engineer (AME).

In Australia, an aircraft maintenance engineer can maintain aircraft and rotorcraft, while a licenced aircraft maintenance engineer deals with structures, powerplants, mechanical and electrical systems and avionics systems. Inspections and repair require a licenced aircraft maintenance engineer. He or she supervises the work of the other aircraft engineers, ranging from AMEs to apprentices and aviation maintenance workers.

An AME must work under the direction of a licenced engineer. The licenced engineer signs off on the work and then certifies that the aircraft is fit to fly.

At Brisbane, the licenced engineer responsible for the line maintenance duties was also the contractor’s regional manager for Brisbane, Wellcamp and Coolangatta airports.

On that day, he was supervising the AME dealing with the Singapore Airlines A350 but he was also assisting with the turnarounds on another aircraft which was parked at the bay next door.

The AME had started working for the contractor three weeks before and had not yet completed induction training. To start, the licenced engineer stepped the AME through the initial external walk-around inspection for the A350.

The AME used an elevator work platform and installed pitot covers on all four pitot probes. This was standard procedure: all aircraft parked at Brisbane Airport have pitot probe covers fitted because of the mud wasps in the area, who love to build nests in pitot probes.

Pitot probes do not work when sealed or blocked. The high population of mud wasps in the Brisbane area, specifically the “exotic keyhole wasp”, has repeatedly caused issues by building nests in the probes, blocking the sensors. The pitot covers stop the wasps from being able to enter the probe. They are attached with streamers in order to draw attention to their placement.

While the AME installed the pitot covers, the licenced engineer went to the aircraft’s flight deck to check the technical log for defects. He noted on the log that the pitot covers had been fitted and placed a warning sign on the engine control pedestal to show that the pitot covers had been fitted. He then went to the adjacent bay to deal with the other aircraft.

The morning continued.

About half an hour before the flight was scheduled to depart, the first officer conducted the pre-flight walkaround. The first officer walked from the nose to the right engine and then cut across to the left engine and back to the airbridge. The walk around should also include walking around the wings and the full airframe and tail, but this didn’t happen. Security footage shows that the first officer looked up at the pitot covers. However, as they were required to be fitted while the aircraft was parked, there was no action required or expected. As far as the first officer was concerned, all was well.

The licenced engineer arrived back at the bay and spoke to the AME about fuel figures. Over the headset, the licenced engineer spoke to the flight crew to confirm the fuel upload.

He returned to the flight deck for the technical log, noting that the aircraft was certified for the transit check. He cleared the technical log entry that the pitot covers had been fitted and he removed the pitot cover warning sign from the flight deck pedestal.

Neither of the engineers had conducted a walk-around of the A350.

Back down on the tarmac, the licenced engineer put the warning placard on the dash of his work vehicle. The problem was that he’d never actually checked the pitot covers were removed. He’d not even asked the AME to remove them, he just assumed that as the AME had reported that he’d completed the work, the pitot covers would have been removed.

Meanwhile, the AME presumed that the licenced engineer would be doing a final walk-around, and thus he didn’t have to.

The licenced engineer returned to the tarmac and met the AME at the nose of the aircraft, where they talked for a few minutes. The tug for the pushback was already in place. The licenced engineer ended the conversation saying that he needed to get back to the adjacent bay to complete the refuelling of the other aircraft.

The AME was left to conduct the headset duties for the pushback, where a tug pushes the aircraft backwards from the terminal until the aircraft is clear and can taxi under its own power.

Over at the adjacent bay, an aircraft refueler looked across to see that the Singapore Airlines A350 seemed ready to push back with the pitot covers still in place.

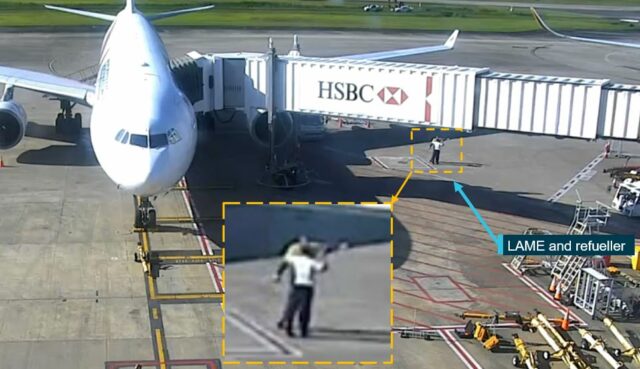

Security footage shows that as the licenced engineer arrived at the adjacent bay, the aircraft refueler pointed to the A350, informing him that the pitot covers hadn’t been removed.

At the same time, the flight crew requested pushback approval from air traffic control and turned on the aircraft beacons.

The licenced engineer must have run back at full speed, as he arrived at the bay just as the aerobridge began retracting from the aircraft.

The flight crew told the AME that they were ready for pushback. The AME asked the flight crew to stand by.

The licenced engineer quickly positioned an elevated work platform on either side of the nose to remove the pitot covers. There were just two minutes until the expected departure time.

As soon as the covers were removed, the tug began pushing the A350 back.

Obviously, we need to wait for the final report; however, it looks as though there are no surprises here. The Maintenance, Repair and Overhaul contractor should undoubtedly come under fire. The LAME did not follow procedures, instead he simply assumed that the job had been done correctly. He may have gotten away with it before, except that the AME was new on the job and still learning the ropes.

The ATSB’s preliminary report was released in August. The Director of Transport Safety made a statement about the ongoing investigation.

From here, the investigation will include examination of flight crew pre-flight inspection procedures, engineering final walk-around procedures, and induction training procedures. It will also examine the engineers’ training records, policies and procedures around fatigue and change management, and more security video recordings.

In other words, they are looking for systemic issues and whether the training and procedures are adequate or if this was an incident just waiting to happen. The investigation level is listed as “short”.

In regards to the flight crew pre-flight inspection procedures, the first officer’s walk around did not actually affect the incident, as the pitot covers were expected to still be in place at that point. However, the video of his truncated walk around has already been highlighted in the preliminary report.

A previous ATSB investigation at Brisbane dealt with a Malaysia Airlines Airbus A330 which took off with three pitot covers still in place. The ATSB described it as one of its most substantive and complex investigations in recent years. That report also showed that pre-departure checks and walk-arounds were omitted or incomplete. In response to this incident, Maylasia Airlines added the requirement for a warning placard to be placed on the flight deck to alert the flight crew to the pitot covers being fitted.

As we saw in this case, that hasn’t actually resolved the underlying problem.

This incident was dealt with just in time, but I hope that refueler got a raise or at least a few beers on the company!

(Also, thanks to AndrewM who pointed me at the wasp problem at Brisbane)

Cheers 😀

I suspect that this comes down to a basic problem with humans: if a thing is OK 95% of the time, it’s easy to file it mentally as OK all the time. I bet if you’d asked the LAME he’d have said “no, I always verify the pitot covers before removing the placard”, but…

OOPS !

I’d can think of two very simple approaches that I think might be very effective in preventing this:

– fit the pitot covers with 6 foot long fluorescent orange plastic streamer (visible probably 100 yds away)

– put a policy into place where the LAME has to pay the refueler (or whoever notices it first) $1000 per cover that was not removed, out of their own pocket.

:)

Problems like this always start at the top. The LAME would not do sloppy work if his supervisor was not sloppy and the supervisor would not be sloppy if his boss was organized.

I spent a lifetime in high risk fields. USMC pilot and Maintenance Officer, DoD contractor and ended up a member of one of Europe’s top Auto Racing teams.

In every chapter of life, the rot always started at the top. It the Boss lies, it is OK for the workers to lie. If the Boss comes in late, it is OK for everybody to come in late.

The job of a leader is to set an example. The workers will follow this example; for better or worse.

Absolutely! Sloppy is the kindest word to describe this incident. After nearly fifty years of USAF and private industry maintenance, I’m frightened by the repeated human system failures we read of almost daily. Checklists came about after many tragic accidents and to ignore or only partially complete them is criminal. Both of the personnel involved in this incident should be removed from their current duties and retrained or dismissed. Unfortunately, too many get second, third and fourth chances to get it right and the result is often death

Culture eats policy for breakfast.

As far as systemic issues, one seems clear in hindsight. It’s always easier in hindsight.

The pilot sees pitot covers in place, and expects the covers to be in place. He expects they will be removed and he expects to not receive confirmation they were removed. Magical thinking.

Functional pitot tubes are so crucial for safe flight that the covers should be off for the pilot’s inspection. Another set of eyes, and in fact the covers were apparently seen in the walk around.

How fast are those wasps anyway?

Mike S: plastic will fray and wear away too quickly, especially in a high wind. However, ISTM that making the current fabric streamer wider and longer, and changing it from red (which excites fewer neurons in the eye) to bright orange would both be good steps.

Ray: I’d also like to know how fast the wasps are; I’ve watched paper wasps at work and was impressed with how busy they looked but not with how fast the nest grew. OTOH, one drop of mud might be enough to be a problem as pitot tubes are not large; ISTM there should be experiments about this, with an eye to considering whether whichever flight officer does the walkaround should expect the covers to be off.

Talking about swiss cheese failures — glad the holes didn’t line all the way up this time.

Dumb question – has anybody ever tried building an automated system to determine if the pitot tube is blocked before takeoff? (Like some sort of pressure test or something?) Or is this one of those things where it’s just too expensive or too difficult to do?

I’m’a invent a pitot with a pneumatic connection that BLOWS the cover off when the FADEC is moved out of idle. I’m’a save lives and be rich too.

In terms of the Safety Management System processes, the holes in the cheese did line up! It was only luck that someone who wasn’t directly responsible for the safety of the flight spotted the issue.

(Does that make them a slice of ciabatta, or other holey bread, then?)

Let’s assume that the wasps are really fast. So fast that the covers can’t be removed before the walk around. So here’s an alternative to the proposal I made earlier.

You need a positive acknowledgment directly to the pilots that the covers have been removed. Remember this process is unusual and almost unique to Brisbane in the way it’s implemented.

To avoid miscommunication, the mechanic that clears the log and remove the placard must be the same mechanic that remove the covers. There needs to be a formal communication to the pilots that yes I have Removed them myself.

Safety Management will always be vulnerable to human error. Human error cannot be stopped by teaching, lecturing, scolding, fining, or firing. It will always persist. It is estimated that 70 pitot covers are burned up on hot pitot tubes every day during maintenance. Searching accident reports also reveals a great many incidents and accidents, many fatal, from retained pitot covers and other pitot blockages. One way to approach human error is to design the system with fail-safes, such as your very good suggestion regarding the pneumatic-releasing pitot cover. In fact, similar technology is available. The PitotShield V2(tm) is currently (2024-25) being launched and in use by one major airline with others in evaluation. One size of PitotShield V2 fits 90% of all aircraft and self-ejects two-to-five minutes after power-up of aircraft with auto pitot heat. For details, visit degroffaviation.com/pitotshield-v2.