Melting Windows

On the 4th of October 2023, an Airbus A321neo located in London Stansted was prepared for a multi-day charter flight in the US. There were three pilots and six cabin crew on board, as well as an engineer and a loadmaster. This first flight was repositioning the aircraft and crew from London to Orlando International Airport in Florida. There were only nine passengers on board, employees of the tour operator and the airline operator.

The three-year-old Airbus A321-253NX was registered in the UK as G-OATW. With so few passengers (depending on configuration, the A321 typically carries from 180 to 220 passengers), the cabin crew boarded the passengers and had them sit in the middle of the aircraft, sitting in the rows before the overwing exits. The additional pilot and the engineer sat in the jumpseats on the flight deck. The loadmaster is responsible for cargo loading and transport in the aircraft. He sat in the cabin, in the row before the passengers.

The Airbus A321 taxied to runway 22 and departed at 11:15UTC, a few minutes ahead of schedule. Everything seemed normal on the flight deck; however, in the cabin, the passengers thought the aircraft seemed a bit noisy and colder than usual.

They climbed away from London Stansted for the 7,000-kilometre flight. As they passed through FL100 (10,000 feet), the flight crew turned off the seatbelt sign.

Curious about the noise, the loadmaster got up and walked towards the back of the aircraft. As he passed the passengers, he found a window seal flapping violently around a slipping window pane on the left side. The aircraft windows were made of stretched acrylic, and the window assemblies consisted of a seal, an outer pane and an inner pane (with a small vent hole so that the space between the two panes was at cabin pressure). The loadmaster couldn’t tell if it was the inner pane or the outer pane which had slipped. He quickly took a photograph and then told the cabin crew what he’d seen as he rushed to the flight deck.

By now, the Airbus A321 was climbing through FL130, showing on the FDR as 14,504 feet at 1013 millibars. They levelled off and reduced airspeed before checking the cabin pressure. The pressurisation system was operating normally; the cabin altitude was just over 1,500 feet. The engineer and the third pilot went to the cabin to inspect the window. The flight crew quickly agreed with them that they needed to turn back to Stansted.

The cabin crew asked the passengers to remain seated with their seatbelts fastened and gave them an additional briefing on how to use the oxygen masks if they should drop down from the ceiling. The aircraft descended to FL90 and flew a holding pattern northwest of the airport while the flight crew ran through the overweight landing checklist, confirmed the landing performance and completed the briefing for the return to Stansted.

They landed safely at 11:51 UTC, making for a total flight time of 36 minutes. Although they didn’t know it, as they taxied to the apron, an outer window pane shattered on the taxiway.

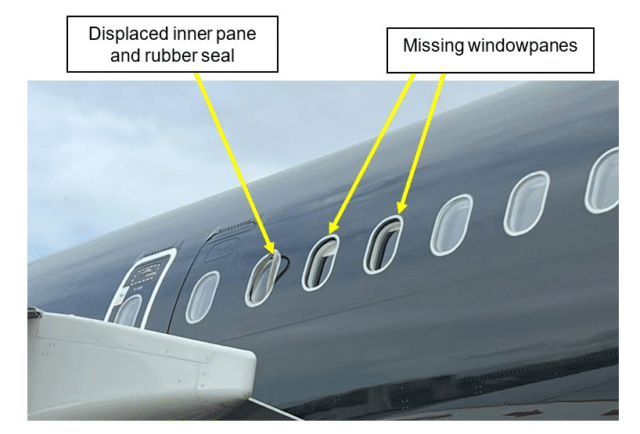

Once the passengers were safely out of the way and the aircraft parked and shut down, they carried out a visual inspection. Two of the cabin windowpanes were missing. Another window had a dislodged pane and a fourth window was protruding from the fuselage. Meanwhile, a runway inspection discovered the pieces of the shattered outer pane on the rapid-exit taxiway.

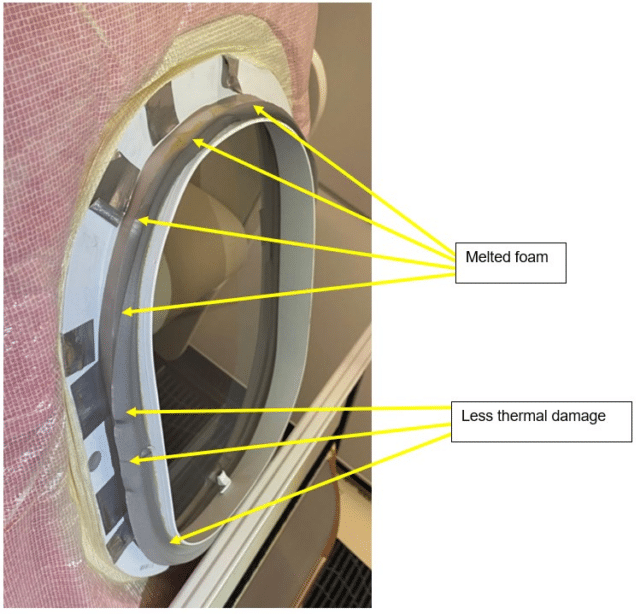

Inside the cabin, they removed panels of the cabin lining on the left side of the aircraft near the overwing exits to look for damage. They found that the foam ring material that surrounded the windows had melted in the areas around the damaged windows. The window panes were deformed and no longer fit into the rubber seals.

There was also a puncture on the underside of the left horizontal stabiliser. The stabilisers are at the back of the plane, parallel to the wings, and are used to control the pitch and attitude of the aircraft. When investigators removed the panel, they found small pieces of acrylic inside the stabiliser.

In a statement on their website, which has since been removed, the operator wrote:

The pilot did not declare an emergency and landed the aircraft safely, according to normal operating procedures. Emergency services at the airport were not activated.

(I’m not sure I like the implication that the situation was less serious because the captain didn’t declare an emergency.)

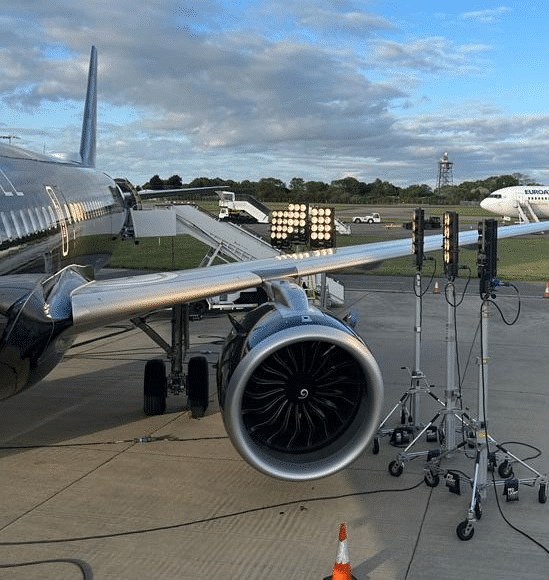

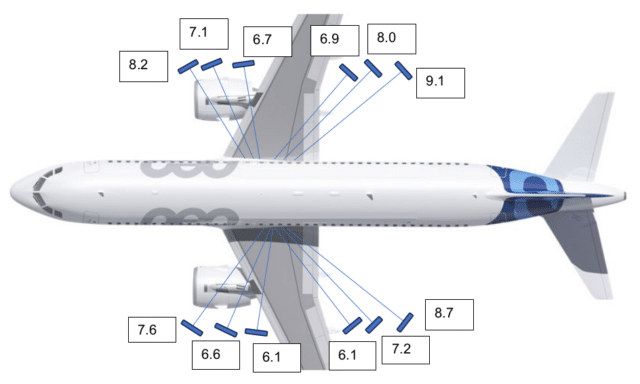

The day before the charter flight, the Airbus had been used for filming. Six sets of floodlights surrounded the aircraft which were identified by the film crew as Maxibrute 12. These flood lights have a lighting capacity of 12,000 watts with a maximum surface temperature of 200°C (392°F). The datasheet warns to keep them at least ten metres (33 feet) from the object to be illuminated. The spotlights had been set up to shine through the cabin windows to mimic a sunrise. The floodlights on the aircraft’s right side were directed at the cabin windows just aft of the overwing exits for about five and a half areas. On the left side, the floodlights were positioned similarly and focused on the windows for about four hours.

Once the British Air Accidents Investigation Branch (AAIB) were on site, the maintenance team removed panels of the interior cabin lining on the right side of the aircraft. They found again that near the overwing emergency exit, the foam material had melted, and the windows were deformed, although there was not as much damage as on the left side.

The AAIB inspected photographs taken during the filming activity the previous day. Using the photographs, investigators were able to reconstruct the layout and prove that the floodlights had not been kept ten metres away from the aircraft, but were positioned between six and nine metres from the damaged window areas.

The high temperatures had damaged and distorted the windows over the four to five hours of filming the previous day. Once the aircraft was in the air, the worst-affected windowpanes became dislodged and unsafe.

Flightradar24 points out that this is not the first time film lighting has damaged an aircraft window. In 2019, a window melted in a brand new Boeing 787-9 under the force of a spotlight used for a promotional video. At the time, this was blamed on the electrochromatic film that the 787 has between the inner and outer window panes, which allows the window to be darkened without shades. However, it’s becoming clear that modern studio lights need to be handled with more care when used to light up aircraft.

The AAIB released a special bulletin, to raise awareness of the circumstances around this latest case. The investigation is continuing with support from the French BEA and Airbus, in hopes of better understanding the issues and risks for using studio lighting around aircraft for future reference.

Luckily, the windows and their settings were damaged such that it quickly became apparent during take off. If the aircraft had reached cruising altitude for the transatlantic flight before the windows began to fail, the damage and the result could have been much, much worse.

As all ended pretty well (some film-maker’s insurance policy is going to go ‘boing!!’) I think I can kibitz a little.

It shouldn’t be too hard to tell if it’s the inner or outer pane – put something over the vent hole (Not your finger! That could be gruesome! Try a safety card or something) and if it swiftly has a vent hole in it too, it’s the outer pane.

But I can’t fault the loadmaster for taking one look at it, probably saying the rough equivalent of “Golly!”, snapping a very quick pic and heading for the flight deck at speed.

The thing that surprised me is they’ve only got nine pax on board. And the thing is still overweight for landing! What were they carrying as cargo, wet cement or something? I guess fuel load being what it is, they’re designed to take off a lot heavier than land.

In my experience, film lights are very very hot indeed, for lots of good reasons filmically, but it’s hot under their glare. Someone shouldda known better.

For me the gotcha here is that the windows are films of acrylic which I don’t associate with a high melting point. I knew they were unlikely to be glass (higher melting point) but why would a non-specialist know about the acrylic?

They would have had a full fuel load to make it to Orlando, thus being heavier than normal for landing

Wikipedia’s numbers for the A321neo have a wide range, but it looks like even the standard model carries about as much weight in fuel as in passengers — and the standard model doesn’t look like it has the range for London-Orlando nonstop. The long-range models could easily carry more weight in fuel than in passengers.

“However, it’s becoming clear that modern studio lights need to be handled with more care when used to light up aircraft.” It reads like modern studio lights (and maybe even older studio lights) need to be handled with more care, period. The website gives the limits; the gaffers exceeded those limits — or were ordered to exceed them by a ~producer who knew what they wanted and assumed that physics didn’t apply to them. (I’m a little heated about limits right now, having recently come back from the site of the 1981 Kansas City Hyatt disaster, where assorted people weren’t thinking about limits when they designed and built a fancy new hotel.)

I would agree with you on that. In my (admittedly brief, but this is one reason why I’m never going back) time in Hollywood I was regularly asked to break the laws of physics, because it would “Look cool”. In what was generally supposed to be believable live-action films.

And they got paid hundreds of thousands of dollars for it. P.T. Barnum was a piker.

Hot windows, cool crew!

An aircraft is a piece of high precision machinery that relies on every part working properly and in harmony to do its job . It should not under any circumstances be used as a film prop, surrounded by people who know little or nothing about aviation. If such aircraft are needed , there are many hundreds lying around in boneyards around the world which I’m sure could be repurposed for film making . The complete carelessness of using high heat floodlights close to a working passenger aircraft , presumably without the presence of any aircraft safety engineers , is unforgivable. This could easily have resulted in a mid air breakup of the aircraft. Whoever gave permission for this appalling debacle needs their head checking .

There aren’t that many aircraft boneyards in Europe, but they do exist.

(Source: both Wikipedia)

There are many considerations that go into choosing a suitable filming location. I’m sure having a film crew inside a “working” airliner is not uncommon, and usually uneventful. I doubt that the loss of 3 windowpanes could lead to a “mid-air breakup” when aircraft survive the loss of a cockpit windshield with minor consequences (see “Sichuan flight 8633 blown windshield” on this blog).

The very fact that airliners are engineered for safety means that they don’t “rely on every part working properly and in harmony”— they’re designed to cope with an engine failure! Mid-air break-ups are very rare, they tend to result from explosions or excessive g-loads or overspeed (typically in an uncontrolled descent). In this case, the interior window-panes held, and the horizontal stabilizer remained functional.

But it wasn’t just 3 window panes was it ? It was 4 just on the left side . It was later discovered that panes on the right side had melted too . And as Sylvia states , if it had reached cruising height before they failed , damage could have been a lot worse. Maybe the horizontal stabilizer could have been compromised ? Why take that chance ? Yes I appreciate they CAN fly with one engine out , but that’s not “doing their job properly” , it’s coping in an emergency. I wouldn’t fancy my chances on any aeroplane at 35000 feet if 7 or 8 windows failed . . . explosive decompression isn’t to be recommended.

If a window failed at 35,000 ft, your chances would be excellent, unless you were the passenger next to that window, and your seat belt was off. The yellow oxygen masks would pop down, and since you’d paid attention in the pre-flight briefing, you’d pop yours on, adjust the strap, and then help the people around you. The pilots would immediately descend to 10,000 ft or less and land at the nearest suitable airport.

If there were more windows to pop out thereafter, even 7 or 8, you’d hardly notice as the pressure would already be equalized. You can only explosively decompress once!

Despite the name, explosive decompression is not an explosion, and will not cause an aircraft to break up in mid-air.

Nobody here thinks that losing even one window is a happy occurrence, but there’s no need to sensationalize it.

Concerning the case at hand, have you ever asked an aviation safety engineer whether these windows are designed such that if the outer pane had failed, the inner pane should withstand the pressure? Because that kind of redundancy is built into many of the aircraft systems.

Well I’m glad you live in such a perfect world , where everyone listens and everything is fine . I just hope I’m not that passenger next to the window !

A 12,000 W incandescent lighting rig strikes me as “traditional” rather than “modern”: an equivalent LED light consumes only 2160W. The difference of 10,000W is heat that the modern LEDs don’t emit. That’s why LED fixture data sheets typically don’t list a surface temperature: they certainly don’t warm up to 200⁰C.

That said, positioning a light at 6.1m instead of 10m makes the incident light 2.7 times as intense. Given that they had 6 of these lights focused on the area, the number of lights had more of an impact than the distance. With the aircraft being outside in October, I doubt its skin heated up much: the ambient air would have cooled it.

But the acrylic double glazing on the aircraft provided a miniature greenhouse:

(Source: https://www.piedmontplastics.com/blog/acrylic-versus-glass )

In fact, acrylic is four times less heat conductive than glass. When an airliner flies at freezing altitudes of -70F/-56⁰C, that’s an advantage. But when there’s a bunch of hot studio lights focused on these windows, I expect the air trapped between the panes gets even hotter than your car on a sunny summer day.

Yesterday, there was a fuselage panel failure, making a much bigger hole:

Source and photos at https://airlive.net/emergency/2024/01/06/breaking-boeing-737-max-9-makes-emergency-landing-after-window-panel-blows-out-mid-flight/

Luckily, the seat adjacent to the hole was empty; no passengers were lost. I commented above, “If a window failed at 35,000 ft, your chances would be excellent, unless you were the passenger next to that window, and your seat belt was off.” Conditions met, outcome as predicted, thankfully.

“They said there was a kid in that row who had his shirt sucked off him and out of the plane and his mother was holding onto him to make sure he didn’t go with it.”

Sounds like a very lucky escape to me . One life lost would be a life too many. They all still had seatbelts on as it was still climbing. Could have been very different at 35000 ft. Conditions not met I’m afraid.

Windows (and plugged door panels) are most likely to fail as the pressure differential across them rises: as the pressure reaches the breaking point, they break. This rising pressure would happen either as the aircraft is climbing, or in turbulence. In these situations, passengers are always required to wear seat belts. It’s not a coincidence. For example, Aloha Airlines flight 243 explosively decompressed as it came out of the climb, which was why all passengers were still buckled up and survived.

The aircraft concerned had been having pressurisation problems for several flights previously, presumably caused by the door plug loosening, so chances are this event could just as easily have occurred at cruising height . Can’t imagine what may have happened in that scenario. Also , it’s pretty lucky the 28kg door plug didn’t collide with any other part of the aircraft, such as the tailplane. Now I’m sure you will come out with some scientific sounding answer as to why this couldn’t occur , but I won’t be convinced. There are many aviation insiders and experts who seem to think this could easily have ended in disaster , so I think I’ll go with their explanations. It seems Boeing have some very serious questions to answer , and are very lucky that they are not facing another complete loss of an aircraft with all on board .