Turning Back with Runway Ahead

The aircraft was a Grumman American AA-5, a four-seater light aircraft developed by American Aviation, which was bought out by Grumman shortly after production started. Registered in the UK as G-BBSA, the Traveler was forty-seven years old. This was one of the original AA-5 Travelers, which ceased production after only one year to be replaced by a more aerodynamic model. G-BBSA was owned and operated by a private syndicate of owners based at Teesside International Airport (originally RAF Middleton).

The Traveler had gone to Sturgate Airfield for its annual maintenance inspection. No issues were found. On the 21st of September 2021, four days before the accident, one of the syndicate members picked up the aircraft for the 45-minute flight from Sturgate back to Teesside Airport. That same day, two other syndicate members flew the Traveler for a local flight which was also about 45 minutes. None of the three pilots noticed any issues with the aircraft.

Teesside has a single asphalt runway, 05/23. Runways are aligned by heading, so in this case, runway 23 would be the runway heading southwest on a heading of 230°.

At Teesside, the pilots parked the Traveler outside, as the hangar where it was normally stored was undergoing renovations.

On the 24th, the day before the accident flight, the pilot filled the Traveler’s tanks but then cancelled the planned flight as a result of high winds.

On the 25th of September, the weather looked much better, with light winds and visibility at greater than 10 km. The pilot called ATC and told them that he was planning a one-hour local area flight with three on board and a fuel endurance of five hours, which means that the tanks were full.

The Traveler is an extended version of the Grumman AA-1 series with four seats and a more powerful engine, the Lycoming O-320, giving it a maximum take-off weight of 2,200 pounds. Fully loaded with four passengers and full tanks, the aircraft’s actual weight that day came to 2,075 pounds. Heavy but within limits.

Runway 23 is 2,291 metres long (just under 10,000 feet). Beyond that is an overrun of 184 metres of asphalt followed by 210 metres of flat grass leading up to the airport perimeter fence. On the far side of the fence, the land slopes down to the River Tees.

Under normal circumstances, the Traveler needs about 900 feet (275 metres) to take off. There was more than enough runway at Teesside for an extended take-off run to compensate for the extra weight.

Once the Traveler was loaded, a passenger in the back seat recorded a video, starting with the Traveler’s engine start and the taxi to runway 23.

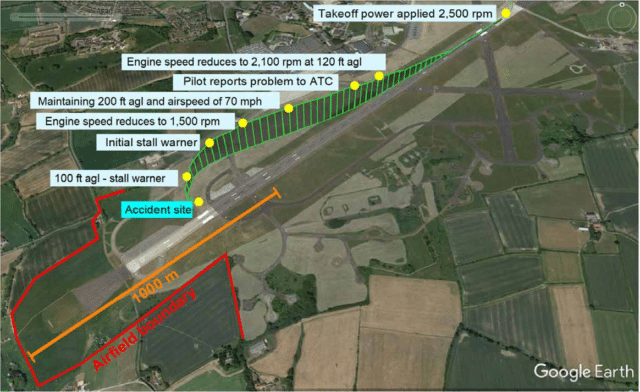

Initially, everything seemed fine. The mobile phone recording showed that the Traveler’s engine was operating at about 2,500 rpm and began to climb at 500 feet per minute at an airspeed of 80 mph.

However, about 14 seconds after the Traveler became airborne, at 120 feet above the ground, the engine sound changed abruptly.

The air traffic controller looked up at the sound. The aircraft had drifted to the right of the runway centre line but seemed to be safely climbing away.

Inside the cockpit, the pilot saw that the engine speed had reduced to about 2,100 rpm. Although the aircraft continued to climb, the airspeed was low. He needed to decide quickly what to do.

He called ATC to report that he’d lost engine power and requested an emergency landing on runway 05 (the same runway in the opposite direction).

The controller diverted an inbound aircraft and cleared the pilot to land on any runway.

Pilots are specifically trained to deal with an engine failure on take-off. Losing power at low altitude needs an immediate response with few options. The instinct to try to return to the runway is known as “the impossible turn” because of the very high risk of stalling the aircraft. It is generally safer to find a field straight ahead and glide to land, rather than use your precious energy and lift to turn back and attempt to land on the runway.

Later, the pilot said he maybe wouldn’t have thought of the option but he’d been practising turnback manoeuvres specifically, using an angle of bank of 15-20°.

Here’s the thing: when the pilot declared that he was turning back to runway 05, he was still over the runway. Before him was 1,100 metres of runway and over 400 metres of asphalt and grass. In a pinch, the Traveler can be landed in less than 500 feet. The pilot had almost 1,500 metres (4,900 feet) to the perimeter fence.

The pilot knew that the aircraft was heavy and needed a longer distance than usual to take off. They were climbing, so he couldn’t see the runway beneath him. It simply never occurred to him that he had any runway remaining.

He levelled out at 170 feet above the ground. Simulations showed that had he continued straight, he still would have landed and stopped safely before the perimeter fence. Instead, he made a slight right turn for a teardrop back to the airfield.

The engine power dropped again. The engine speed reduced to 1,500 rpm. At this point, the Traveler was 200 feet above ground level with a heading of 245°, just 20 degrees off of the runway. Simulations showed that if he’d maintained that heading, he still had 600-1000 metres of flat land before reaching the perimeter fence.

However, having decided that he had already left the airport behind him, the pilot did not register his situation or reconsider his decision to turn back. At the same time, he was likely going through the engine failure checklist. He turned left as the aircraft passed over the runway threshold.

A person who was tending to a horse in a nearby field said, “I heard the plane engine start to sputter, then looked up to see it bank left sharply. The engine sounded like it was really struggling, then it just seemed to cut out.”

The airspeed dropped to 64 mph (56 knots). The stall warner sounded briefly as the left turn continued. The aircraft was quickly losing altitude, with a descent rate up to 1,000 feet per minute.

The stall warner sounded again. They were just a hundred feet above the ground. The angle of bank had reached 40°, much too steep a turn for an aircraft flying low and slow.

The pilot lost control. The left wingtip struck the ground. The nose ploughed into the grass. The Traveler spun 180° and then came to a rest. The wreckage was thick with fumes: the fuel feed pipe had fractured, emptying all of the fuel in the left wing tank. The right wing tank still held 32 litres of fuel.

The entire flight had lasted 67 seconds.

The controller immediately declared a full emergency, diverting inbound flights to Newcastle. The person tending the horse saw the plane drop rapidly and heard the sounds of impact. They phoned emergency services to report what they had seen.

A member of the Rescue and Fire Fighting Services had been driving around the runway to frighten off the birds and quickly drove to the crash site. He cut off the aircraft’s fuel and power and helped the pilot and the passenger escape the wreckage. At the same time, ATC phoned Emergency Services; however, somehow it was ten minutes before they were able to demand immediate assistance from the fire services . “It took a long time to speak to someone,” said the controller later. Because ATC had a direct contact for the Air Ambulance services, the Air Ambulance helicopter landed on the scene before the Fire Services had even been notified.

The investigation focused on the carburettor, which had 601 flying hours over six years. The manufacturer recommended a maximum of 2000 flying hours or ten years in service before an overhaul, so it was still in date. The aircraft had just completed an annual maintenance inspection, in which a new propeller and replacement nose landing gear were fitted. The maintenance engineer visually inspected the carburettor and airbox but had not removed them as a part of the standard maintenance.

After the accident, the carburettor was still screwed to the engine sump. There was no evidence of water or debris. The throttle and mixture control linkages were securely attached to the cockpit control cables. Investigators started the engine. Three of the four engine cylinders showed normal compression; however, cylinder no. 4 showed no compression at all.

The wreckage was transported to the AAIB facilities for further examination. There, they found that all four cylinders showed a normal degree of compression.

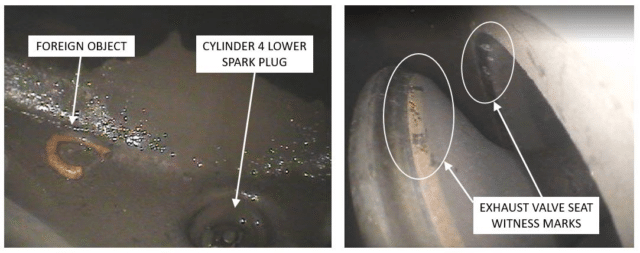

The investigators examined the engine with a borescope, a tool which is inserted into the engine to examine the internal components without needing to disassemble the parts. They found a small, C-shaped foreign object in the cylinder.

This object had left marks on the exhaust valve, where it had blocked the valve from closing correctly. The No 4 cylinder showed many impact marks, whereas there were none on the other three cylinders. They concluded that the object had been trapped beneath the exhaust valve at the accident site, which was why there was no compression from cylinder 4. Then, it came loose when the engine was transported to the AAIB facilities, which is why in the later test, all four cylinders showed normal compression.

A metallurgist was brought in to examine the foreign object. He identified the object as a section of brass tube composed of “cartridge brass” (an alloy of copper and zinc) with an average hardness value of 95HV. The carburettor manufacturer confirmed that this was the same material used for the accelerator pump discharge tube. The hardness condition specified for the tube was ½ hard, or 126 HV.

The measurements of the foreign object matched the discharge tube. The metallurgist considered that the lower hardness value was consistent with the tube being subjected to the high temperatures of the No 4 cylinder.

Having gleaned all the information they could, they disassembled the carburettor and confirmed that, yes, the accelerator pump discharge tube was missing.

This is a very rare event. There are no other cases in the UK where the discharge tube has become detached. In the US, only five events are listed in the FAA database. All five of these events were Lycoming O-320 engines, just as with the accident aircraft.

There was no explanation as to why the accelerator pump discharge tube had broken off; however the effect was clear. This tube was sucked in from the carburettor into the cylinder, where it blocked the seal during the engine power stroke. Thus, the engine was running on only three cylinders, causing a considerable loss of power.

The engine suffered a partial loss of power during takeoff due to a portion of the accelerator pump discharge tube having been released from the carburettor into the No 4 cylinder. Following this partial loss of power at low altitude the pilot decided to turn back to land, although post-accident analysis of the circumstances shows there was a sufficiently clear area ahead in which to effect a landing. During the turn, at a low airspeed, the aircraft stalled and struck the ground. All three occupants sustained serious injuries in the impact.

The pilot was seriously injured and so was not interviewed until much later. He said that he had done the pre-flight checks, including checking the fuel for water contamination. The engine start, taxi and power tests were all normal. He recalled being around 400 feet above ground level when the engine lost all power. He said he then lowered the nose to maintain speed.

A part of pilot training is to think through potential accident scenarios, including an engine failure after take-off. The pilot had considered this possibility before. The River Tees passed by the far side of the airport, yes, but he knew that there was a field directly ahead of him which he could land on if he lost power.

However, when it came to it that day, he thought that landing on the field would be dangerous, as there were animals and people on the field. He could see no other option to land ahead. He pulled out the Engine Failure checklist and, as far as he recalls, he followed it.

His perception, and possibly his recollection, was faulty. He was nowhere near 400 feet above the ground and if he’d lowered the nose and looked for landing options, he would have seen that he was still over the runway. The rest of the flight is even more confused. He said that he quickly decided that he wasn’t going to make it to the runway and instead chose a patch of green. “It looked good enough to land. Good area. I put it down there.”

Then, as he recalled, he came down just fine, flaring the aircraft to land on the green area. The stall warner, he said, sounded just before touchdown.

The wreckage showed a fast impact in a nose-down, left wing low attitude.

There’s no analysis of this in the report. It feels to me like this is a recollection of how the pilot played out the scenario in his head as he entered the turn, whereas actually he lost control shortly thereafter and was never in a position to flare.

When it was first clear that the engine wasn’t producing enough power, the Traveler was at 120 feet above ground level and there were 1,300 metres of runway remaining. The Traveler could have landed and stopped in this distance. However, as the nose was high for the climb, it would not have been easy to see how much runway was left. The pilot lowered the nose to maintain airspeed but even at a level attitude, it may not have been obvious that there was runway still ahead. At that point, the Traveler had enough power to maintain airspeed and even to climb another 60 feet.

Six seconds elapsed between the initial engine power reduction and the pilot asking for runway 05. He still had plenty of runway left at this stage but the nose may have still obscured his view. The engine continued running at 2,100 rpm for about ten seconds. The Traveler maintained a speed of 70 miles per hour and an altitude of 200 feet above ground level.

When the engine power reduced again, the Traveler was still 200 feet above the ground, about 140 metres to the right of the runway with a heading of 245°. If he’d decided at that moment that it was safer to land quickly, he could have turned just a little left and had a landing distance of 1,000 metres to the airport boundary.

Instead, he turned back to the runway that he thought was behind him. He may have already decided that he would have to land on the grass; nevertheless, he entered a steep turn to try to make it around.

At an angle of bank of 40°, the Traveler has a stalling speed of 71 miles per hour. But as the engine power had reduced again, the Traveler was only at 64 miles per hour as it entered the turn. As the angle of bank increased, so did the stalling speed, which quickly became higher than the actual airspeed.

Low to the ground at a slow speed and a high angle of bank is a classic scenario for an unrecoverable stall. The instinct should have been to land ahead, even in less favourable landing conditions. The pilot probably would have if the engine had failed completely. He’d been trained with a simple set of checks and procedures based on a forced landing straight ahead.

A partial power loss is challenging in its own right. If the engine is out, the only possibility is to glide to a landing. However, with some engine power remaining, there are more possibilities and an opportunity to improve the situation for a safer landing.

An AAIB study of accidents between 2000 and 2010 showed that there were no fatal accidents where the engine had failed completely but nine fatal accidents after partial power loss. That same study also showed that partial power loss was almost three times more likely to occur. There were a further 16 partial power loss cases between 2011 and 2021, leading to 15 fatalities and 9 serious or life-threatening injuries. Two of the cases had no injuries; in both cases, the pilots continued under control to a successful forced landing. Five of the pilots attempted turnbacks and every single one resulted in fatalities or serious injuries.

And yet, pilot training focuses on the total power loss. The pilot had not considered his actions in the case of a partial power loss on departure, nor did he have any mental table of the safe heights at which to attempt a turnback. The flying school at Teeside did not teach turnbacks and had never done them as a part of their training. At a larger operator, turnbacks were trained but only at 700 feet above ground level and only with an instructor on board. The other pilots in the same syndicate said that they had not considered turnbacks and that they’d been trained not to turn back in the case of a power out. The pilot’s decision to practice turnbacks likely caused him to see this as a viable option, without understanding that he needed to check the height and airspeed before attempting the manoeuvre..

Australian PPL training includes a “partial power loss event” as a part of a forced landing exercise, although this is not directly after take-off. Their Civil Aviation Safety Authority (CASA) recommends that in the case of a low-power landing, turns should not even be attempted below 200 feet: continue with a straight climb or a descent to land with a focus on maintaining airspeed.

The pilot was very familiar with the aircraft and the airfield. If his training had included partial power loss events, he may have taken the time to consider, before the flight, what he needed to do in the case of the engine still functioning but failing to produce enough power, just as he had for the event of a total power out. He could have understood in advance that the best course of action was dependent on his height above the ground. This may also have helped him to consider more seriously how much runway he had left, even though he could not see it in the climb.

The report concludes that it would be helpful to discuss this scenario as a part of the PPL training and rating re-validation in single engine aircraft, so that pilots have a better understanding of the techniques for managing a partial power loss situation.

Couple of typos:

“The air traffic controller looked up and the sound. The the aircraft” probably should be “The air traffic controller looked up at the sound. The aircraft”

“There are no other cases in the UK where the discharge tube has become attached” probably should be “There are no other cases in the UK where the discharge tube has become detached”

Sorry… the OCD speaks…

Also, “which is why in the later test, all four engines showed normal compression.” should be “which is why in the later test, all four cylinders showed normal compression.” (Para 35).

Thank you both. Fixed these and two other errors pointed out to me in email. I thought I’d left enough time for proofing but apparently not!

Great writeup, thanks Sylvia.

How many hours did the pilot have? How many recent hours? How long had it been since an instructor reviewed his pilot skills? (In the US, a requirement for a biennial flight review by an instructor came in about the time I got my PPL, but the instructor who did mine took it pretty lightly.) This would be tough situation for anyone; for a non-commercial pilot with no other qualified pilot on board, and possibly not a lot of recent experience (let alone practice for difficult situations), it’s downright nasty. (I’m not surprised that a partial failure is more dangerous than a full failure; there are more decisions to make.) In this situation (so close to the ground) it’s not clear that spending time on an engine-out checklist (except for what might have been in his head) is useful; it’s easy to say that he should have been aware enough of his surroundings to put the nose down and land, but with someone behind him shooting video he might have been distracted — or had an ego problem.

The recollections afterward being at odds with what happened isn’t surprising; IIUC, serious injuries can scramble just-passed memories.

The engine failure checklist is reproduced in the report, and it’s mostly useless for a partial failure. I can see a pilot spending time on it if the aircraft was still able to maintain altitude. Where jet pilots practice “1 engine out” procedures, maybe rotary engine pilots should practice “1 cylinder out” situations?

The first item on the checklist is the most useful, which is to maintain 83 knots airspeed for best glide ratio. Clearly the pilot didn’t pay attention to that, as the speed was 80 knots in the climb and deteriorated from there.

The rest of the checklist is concerned with restarting the engine, and marginally useful if it’s still running: you won’t be on an empty tank or have a fuel pump problem. If you fail to restart the engine, you’re supposed to shut everything off; again, not useful if the engine is still somewhat running.

If there was a “partial failure” check list, it might be about the ability to maintain altitude; about planning a safe flight path, and avoiding steep turns; and about the likelihood for the engine problem to get worse, and what to do so it doesn’t. Treating it like a full engine failure, and with the same urgency, may not be warranted and cut off viable options. What do you think?

I think such a list could be useful IFF it were sectioned by altitude — as in, if you’re below 500 feet just find the least-bad place to set down; if you’re above 1000 feet try A, followed by B and C if you’re still above some cutoff altitude. (I’m not even sure of this as it could easily overload a single pilot even without passengers possibly getting on the pilot’s nerves.) A single-engine aircraft doesn’t have the kind of time to investigate that a multi does.

Given the fraction of partial engine failures that turned fatal, I’d be really wary of suggesting that a private pilot can do more than in a complete failure, but I never learned anything more about A&P than what’s taught to the average pilot. Are there any engine experts here who can suggest whether anything useful could be done? Such advice should probably come from manufacturers, but I can’t see them risking being held liable when somebody augers in while trying to fix the unfixable.