HAV Airlander 10 incident in 2016

On the 24th of August 2016, a test flight of the HAV Airlander 10 registered G-PHRG ended badly. Well, the test flight itself was successful. With aircraft, take-off and landing are the critical phases of flight, while most airship issues seem to occur after the flight is finished, when the airship is parking. Or rather, mooring. But I’m getting ahead of myself.

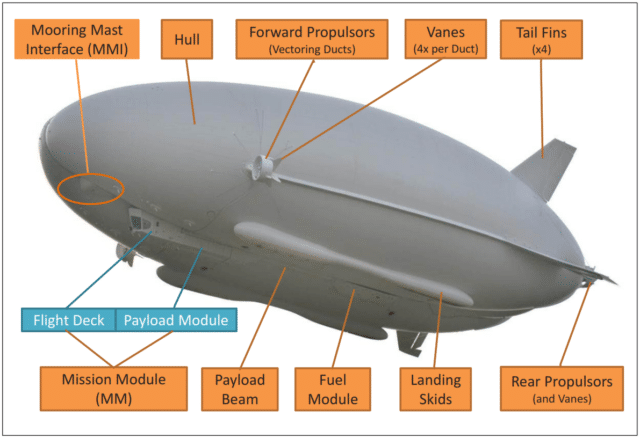

The HAV Airlander 10, designed for air cargo transport, is described as a hybrid mix of helicopter, aircraft and airship. HAV say that it can reach 16,000 feet and travel up to 90 miles per hour with the capability of staying aloft for up to two weeks. It can also carry up to ten metric tones (22,050 pounds) of cargo.

It’s an example of a lifting body, which uses aerodynamic principles to produce lift from the shape of its fuselage, rather than relying on wings to generate enough lift to carry the weight of the body. We looked at the principle before in the context of NASA’s M2-F1 which led to the design of the space shuttle.

I took two pages of notes on the subject which ends with a scribble of “I have no idea how this could possibly work” so I’m going to quote the HAV people on the physics:

The buoyancy of the aircraft is expressed in terms of static heaviness. A static heaviness of zero would equate to neutral buoyancy, such that the aircraft would neither rise nor fall unless acted on by other forces. In normal operation the aircraft has positive static heaviness, being overall heavier than air. Generally, static heaviness reduces as fuel is burned and it may also be affected by precipitation and by environmental warming of the helium gas.

Because it uses both aerostatic and aerodynamic lift, it is neither an airship nor an aircraft. As I understand it (which is to say, “barely”), the Airlander takes off by vectored thrust and once airborne, it transitions to forward velocity which creates lift over the body, keeping it airborne. The buoyancy of helium is used to reduce the amount of lift the Airlander needs. It receives 60% lift from buoyancy, 40% lift from aerodynamics and 25% from vectored thrust, where the vectored thrust seems to be used only during take-off and landing.

Shareholder Bruce Dickinson (who figured hugely in my teenaged years as the lead singer from Iron Maiden but he seems to have moved on since then) explains it like this:

Barnes Wallis R100 airship of the 1920s was a great design but was limited by the technologies of the day. The construction materials were inadequate, the engines were heavy and inefficient, flight controls were cumbersome, radar didn’t exist and navigation and weather forecasting were still at an early stage of development. In later life, Barnes Wallis wrote a note for Roger Munk, saying: ‘Solve these problems and the airship will become an efficient and viable mode of transport.’ The issues to be tackled were stability and flight control, structures, increased payload, more powerful engines, improved capabilities in poor weather and forecasting and easier ground-handling. Now we have the technology to revisit this fundamentally sound design to make it efficient and make it work.

The first test flight of the HAV Airlander took place a week earlier, on the 17th of August. The Guardian waxed poetic:

Above a field in rural Bedfordshire, a shiny, futuristic craft the size of a football pitch ascends majestically into the evening sky, and gawping onlookers crane their necks for a better view. This could be the trailer for the latest Independence Day film, but it is the maiden flight of the Airlander 10, a helium-filled craft aiming to kickstart a new age of the airship.

It has been a while coming – the first flight had been delayed several times and Wednesday’s takeoff was held up for hours – but once in the air, showing off its curves as it banks and soars for its audience, the Airlander is quite a spectacle.

The second test flight took place on the 24th of August. There were two flight crew, a test pilot and a flight test engineer, on the flight deck of the Airlander, a 15-foot long area with four floor-to-ceiling windows. The Airlander was originally designed for unmanned flight so the cockpit on the flight deck was added later. The cockpit has Garmin avionics and a GNS 430 GPS/nav/comms system. There is also a screen fed by cameras installed 15 feet ahead of each engine to allow the pilot a view of the engines, which aren’t visible or even audible from the cockpit. The pilot controls the Airlander with a side stick on the right side.

The flight crew were supported by two teams on the ground, the flight test team and the handling team. The Airlander unmasted at 08:12 for the flight. There was a gentle breeze of around two knots. The crew went through a sequence of test flight tasks and declared the flight a success after about 98 minutes. They returned to Cardington.

Cardington is interesting in its own right. The site of the airfield is a former Royal Air Force station in Bedfordshire, England; this is where the first British airships were built during and after the first world war. Short Brothers, an aerospace company founded in 1908 in London, was the first company in the world to make production aircraft. In 1916, they received a contract to build two large dirigible airships for the Admirality, the British government department responsible for the command of the Royal Navy (its functions are now carried out by the Navy Department of the Ministry of Defence). A 700-foot long (210 metres) airship hangar was built in 1915, which was known as the No. 1 Shed. A housing estate for the employees was built nearby, which is still known as Shortstown.

The airship site was nationalised in 1919, becoming the Royal Airship Works. Between 1924 and 1926, No. 1 Shed was extended for the R101 project, raising the roof by 35 feet and increasing the length to 812 feet. The No. 2 shed started life in Norfolk but was dismantled and re-erected at Cardington.

The R101 crashed during its maiden voyage in October 1930, destroying the aircraft and killing 48 of the 54 people on board. The British government cancelled further dirigible funding and the German Zeppelin Company, purchased the duralumin from the wreck, possibly to re-cast and use in the Hindenburg. Cardington became a storage station.

However, it came back into play in 1936, when the RAF used the site for building barrage balloons: tethered kite balloons meant to defend ground targets from aircraft attacks. The British Balloon Command was established in 1938; barrage balloons were used to protect key targets from dive bombers by forcing them to fly higher. Cardington became the main RAF Balloon Training Unit and by 1940 there were 1,400 barrage balloons in place, a third of them over the London area.

Germany began to use more high-level bombers and the effectiveness of the barrage balloon waned, but Cardington remained busy as it became the home to the RAF meteorological research balloons training unit in 1943 until 1967. The sheds appear not to have been in use, however, as the fence around the site was moved, leaving the sheds outside of RAF Cardington.

The Met Office is still using the site for a Meteorological Research Unit, with a tethered balloon kept in a small, portable hangar. In 2007, English Heritage added No. 1 Shed, by now known as Hangar Number 1, to the At Risk Register. The hangar is a Grade II listed building as the only in situ example of an airship hangar to have survived from the pre-1918 period, however the cladding was failing and the condition deemed to be “very bad”.

In 2015, Hybrid Air Vehicles reopened the completely repaired and refurbished hangar and brought their workforce there to completely development on their hybrid airship, with a press release inviting the public to look out for the Airlander 10 in the skies of Bedfordshire in early 2016.

Where was I? (Actually, I’m thinking about writing a new book in which I collect all these pieces where I fall down a research rabbit hole and highlight them instead of the main story. I would call it What Was I Talking About Again?)

On that day, the 24th of August 2016, the HAV Airlander had completed all of the planned tasks for the test flight and was returning to Cardington. Traditional airships were lighter than air which meant a large ground team was required to lasso them down to the ground. The Airlander is able to make itself heavier than air in order to land more effectively. However, it’s not capable of a true vertical landing: the Airlander can’t just drift over the landing area and then drop down. In order to land, the Airlander approaches the landing area with some forward airspeed, touching down with a short landing roll as the aircraft naturally slows to a stop.

The flight crew brought the Airlander in for landing.

The mooring line is normally stowed within the Mast Mooring Interface, the housing for the TMM, a towable trailer with a telescopic mooring mast which secures the Airlander to the ground, similar to a buoy for a boat. In the stowed position, the free end of the mooring line is attached to the aircraft at a point just below the flight deck windscreens. As the Airlander lands, the ground crew members detach the free end of the mooring line and pull the line out of the Mast Mooring Interface and feed the free end into a winch at the mooring mast. This allows the Airlander to be winched into the mast and secured.

The ground crew extracted the mooring line from the Airlander’s stowage, ready to feed it into the winch at the mooring mast assembly. The mooring mast assembly is driven by hydraulic pumps which are powered by a diesel engine. But the diesel engine wouldn’t start: the starter battery had been drained by an electrical fault.

Now they had a problem: if they couldn’t start the engine, they couldn’t winch the Airlander to the mast.

The test pilot decided to gain altitude in what seems like a very slow version of a touch and go.

There’s no proper storage for the mooring line once it has been extracted from the MMI. The flight crew quickly found a place temporarily stow it through a small access panel in the cabin door.

As the Airlander left the ground, the mooring line fell free under its own weight until the full length was hanging down, about 155 feet (47 metres).

The ground team warned the test pilot that they had about 50 feet of the mooring line dangling from the Airlander, apparently not realising that the full line had pulled free. The pilot remained airborne while the ground team resolved the issues with the diesel engine and the winch. Then, mindful of the mooring line swinging beneath him, he flew a steeper approach in order to avoid the line getting tangled in the trees or the perimeter fence beneath the airship. Effectively, he was trying to get as close as he could to a vertical landing in the very light wind conditions.

The pilot believed that the rope was only dangling about 55 feet and thus would clear the power lines which crossed his approach path, which were about 120 feet above the ground. The mooring line swung into one of the high voltage power cables. The test pilot managed to free the line from the wire but now the Airlander was at around 180 feet, high for the final approach. With no forward airspeed, the pilot had limited control. He trimmed the Airlander nose-down in hopes of bringing the mooring line within reach of the ground crew. This is done by using ballonets: bags in the hull which can be inflated with air to increase the mass of the airship and compress the helium. CTO Mike Durham explains:

As you go up in altitude, the air wants to expand and you can’t cope with trying to contain it with the strength of the hull, so the helium pushes down on the ballonets and pushes air out through valves. When you come back down the helium wants to contract, so the ship would go soggy unless you push air back into the ballonets. So each ballonet has a big valve and fan in it so can vent air in and out and run the ship at a constant delta p. It’s the one system on the vehicle that’s got no parallel to any other aircraft or helicopter.

The key point here is that you can use the ballonets to adjust the centre of gravity; if you only inflate the ballonets at the front, the bow becomes heavier which pitches the nose down.

The pilot had the Airlander pitched to about 10° nose-down when the airship suddenly lurched to 18° nose-down and started to descend. The pilot attempted to reduce the nose-down angle but he couldn’t slow the descent. The Airlander crashed nose-first into the ground, causing structural damage to the flight deck.

The flight crew were evacuated through the gaps in the damaged flight deck and the HAV was attached to the mooring mast and secured.

The gentle crash took place at a somewhat different speed than we are used to in aviation, as you can see in this video (readers on the mailing list may need to click through to the website to view). The video footage begins with the Airlander attempting to correct before eventually coming down with a bump. One person described the attitude of the Airlander as “a very slow motion tumble”, with the nose too low and the back end too high.

Hybrid Air Vehicles said that the repairs should take about three to four months, however some of the specialist tools they needed for the repairs had been scrapped by the US Army and would need to be remade, which would “contribute significantly to the estimated time required”.

HAV ran their own investigation on the test flight and submitted the results to the AAIB who referred to it for their special bulletin for March 2017.

The investigation determined that the higher than planned approach had been necessary in order to allow sufficient clearance for the mooring line. In turn, the mooring line had come to be hanging free below the aircraft because there was no proper stowage facility for the mooring line once it has been extracted from the MMI. The high approach led to a situation that was considered outside of the aircrafts normal operating regime, in that it required a controlled vertical landing in very light wind conditions. The static heaviness of the aircraft had probably reduced as a result of additional environmental heating occurring between the first and second approaches.

Static heaviness is the ratio of buoyancy to gravity. To increase altitude, you need to reduce the craft’s static heaviness, to allow it to rise. To descend, you increase the craft’s static heaviness. It seems like until this point, there wasn’t a specific consideration of naturally occurring changes to the static heaviness over short periods of time.

The internal investigation concluded with a number of recommendations including:

- effective stowage and control arrangements for a deployed mooring line

- review of relevant static heaviness issues

- enhanced maintenance and fault reporting regimes for ground support equipment

The flight crew on board for the test flight walked away with no injuries and the cabin survived the low-speed incident. Hybrid Air Vehicles decided to design a new landing system to allow the Airlander to return to the ground from a greater range of angles, as well as a system for easier recovery of the mooring line.

The repairs were quickly completed, however in November 2017, the Airlander 10 suffered a second accident and this time, HAV decided it was not worth restoring the prototype. This meant that HAV was an airship company without an airship, and at the time it seemed questionable whether they would continue. However, HAV is still around, now with a focus on mass production opportunities and with new funding from a number of sources.

Bruce Dickinson is still the leader singer of Iron Maiden! He’s also a pilot. Their 2015 album “Book of Souls” closes with the track “Empire of the Clouds” which tells the story of the R101 airship that crashed on its maiden (pun intended) flight in 1930.

Well, teenaged-me didn’t think I’d ever say this in my 50s but clearly I need to pick up the Iron Maiden album!

Teenaged-me would probably be equally surprised that, having been to see Maiden as my first ever gig in ’83, I was still going to their gigs in the 2010s…!

He’s also doing an autobiographical show, last two tour dates in December:

https://www.ticketmaster.co.uk/an-evening-with-bruce-dickinson-tickets/artist/5305833

I read “there’s no proper storage for the mooring line once it has been extracted” and my software-developer brain started ringing alarm bells and I thought “what kind of idiot design is that? … and what other stupid design decisions have they made?” – I didn’t think that’d be sufficient in itself, but it was!

The video is the epitome of “slow motion train wreck” and it it just seems really obvious that those two fans are just simply not enough control authority. Am I wrong here?

“Some of the specialist tools they needed for the repairs had been scrapped by the US Army” – really? They didn’t buy the tools they might need to maintain their sole reason for being in business? Especially since they’re “scrap” they’d be cheap?

They don’t seem too competent, and now they don’t even have an airship. Who are the idiots giving them money, and can I have some too? What are they mass producing?

That was also my reaction to the lack of retractability — somebody was making a very large assumption about never needing to go around from below some critical height.

OTOH, the tools they needed were probably scrapped several thousand miles (and untold layers of bureaucracy) away; maybe some clerk said “Their only use in the last decade was some crazy Brits going on about airships” and assumed no communication was needed, or maybe the communication got interrupted somewhere, or the Airlander team didn’t hear until too late that they were the only users of that tool. (One is reminded of a recent article about the amount of BBC TV tape that was recycled, ~”because nobody will ever want to see a second time something done for lowbrow entertainment.”)

It surprised me too. It does sound as though they assumed that it would never be needed, and “it will always work first time” is definitely one of the more dangerous forms of optimism.

As for the specialist tools, Hybrid Air Vehicles may never have had any option to buy them from the US Army even when the tools were due to be scrapped. No doubt there’s a huge amount of strict regulations governing the disposal of US military property, especially when the potential buyer is outside the United States.

It was clearly a risk for the company to be dependent on equipment that it couldn’t guarantee having access to in future, but I can also see how it might have seemed reasonable to them to refrain from developing any alternative until they had to, in order to defer the costs.

I understand that airship accidents tend to happen, even from the point of view of those on the flight deck, with a great slowness and sense of inevitability.

I assume the lack of proper mooring line stowage (and a winch, etc.) is an effort to save weight. And at least it’s not a true hybrid helicopter-airship design like the Piasecki PA-97, four helicopter bodies on a framework under an airship, which turned out to be horribly vulnerable to resonance modes.

Three very good analyses of the vulnerabilities of airship design and their problems by Gene Cash, CHip and RogerBW.

What is eminently obvious, and has been since the R101 crash, is the problems that airships encounter when operating in difficult weather situations. And “difficult” may be “benign” when it applies to fixed-wing, even ordinary rotor-wing aircraft.

The total weight of an airship is always very low, even if the total weight of its components is not. The buoyancy of the lifting medium, be it hydrogen or helium, ensures that “on the scales” an airship will weigh very little compared to its size.

And therein lies a problem: A very large and very light object will inevitably be affected by weather.

My very first job as a commercial pilot was towing advertising banners.

This was for a German company with the rather tongue-twisting name of “Westdeutsche Luftwerbung Theodor Wuellenkemper K.G.” Even for Germans this was a bit much, so it was changed to the more manageable “WDL Flugdienst”.

The CEO was actually ahead of his time. He invested in Ballonfabrik Augsburg which gave him access to the technology he needed to develop and build his own Blimp airships. This included an already existing airship which was airworthy and transferred to the WDL home base of Essen-Muelheim. It was registered D-LEMO.

A large hangar was erected to shelter the blimp against adverse weather, but soon a problem arose when it was found impossible to bring the airship inside during high winds. The wind direction was across the entrance and prevented the ground crew from bringing it in.

It had to stay outside on its mooring mast and was destroyed.

WDL had a large workshop built for the construction of blimps. It was actually similar to the structure of the airship: Impregnated and coated cotton fabric. The first workshop was damaged during a storm, but I believe that it was eventually repaired or replaced and twelve blimps were completed to replace D-LEMO. They were used for aerial advertising.

Apart from wind, the airship faced other problems: In winter even a light coating of snow or rime ice could cause the top of the outer shell to sag, thus losing aerodynamic integrity just when it needed all it could muster. Even rain could increase the weight of the airship to a point where it no longer would have enough thrust to remain airborne.

Even though the hull was coated with silver-coloured paint, exposure to sunlight could cause the gas inside to warm up and expand, causing overpressure but, simultaneously, a noticeable increase in buoyancy.

The ads that were placed on the sides caused problems that took a long time to iron out, as it meant that sections were unevenly heated or cooled down compared with other parts of the lifting hull.

The scenes in the video make it eminently obvious that the loss of a vectoring engine made the crash all but inevitable.

And yes, I agree: what i…ot agrees to invest in a project to build airships AFTER critically important tools have been destroyed?

The US Navy had nearly unlimited funds to build them. To replace them will be a very expensive exercise for a commercial company, especially one that is already short on cash.

But another factor will prevent widespread use of airships: the lifting gas itself.

The Hindenburg disaster is well-known. It was most likely caused when static electricity, generated when the airship made contact with the mooring mast, ignited leaked hydrogen gas. As we all know, hydrogen gas has a greater lifting capacity than helium, but is highly inflammable.

Helium is an inert gas.

But the problem is: it is a finite resource. When it leaks away into the atmosphere it cannot be replaced. There is already a very limited amount of helium in existence, it is questionable if there will be a supply sufficient to support a fleet of airships.

I like the idea of airships: economical, relatively cheap with a minimum impact on the environment.

But it does not look as if airships will be the answer to this world’s transportation problems.

I am reminded of the old saying about aircraft design: “If it looks right, it is right.” The horizontal double-bubble Airlander does not look right. From the front, it looks like a person’s bottom.

Roger, that is an opinion that need not be shared. Actually, from other angles rather than the somewhat distorted close-up it looks good.

The problem, as I have understood it at the time when I worked for WDL, is that it is a better proposition in some climates than in others.

The blimp is rather vulnerable to high winds, and in the west of Europe we may have lots of it.

As long as operators have the luxury of determining when it is necessary to take their airships to safety they can be operated with a reasonable amount of reliability.

The rigid airships like the Zeppelins and R 100 and R101 had a metal skeleton and did not deform under certain conditions.

But there were other limiting factors, as has been demonstrated.

But insofar as I understand, the limited amount of helium that cannot be replenished will be a major limiting factor.

Rudy — I am struck by “The wind direction was across the entrance and prevented the ground crew from bringing it in.” Many airports show traces of runways thrown up in haste and found to be unnecessary; see, e.g., Hanscom Field’s 17/35 (built as WW2 was imminent, long out of use when I started lessons in 1973, but still ~90% visible as taxiways and apron boundaries), or the star-of-David design that Heathrow began with. But this hangar went up at an existing base-of-operations; how could the CEO not know which way the wind blew?

I’ve seen scraps of info over the years suggesting that the Hindenburg’s burning was catalyzed by impurities in the hydrogen, and even that there are suppressant materials which could further reduce the chance of fire — but AFAIK nobody has been impressed enough to put up the money for a full-size demo. And you’re right that helium is non-renewable (and may become even harder to find as we slow down extraction of natural gas, which is the primary source); it’s not clear airships will ever be viable.

I suspect that any significant revival of airships, outside of a few specialist applications, will depend on developments in materials science. The innovative use of new materials might allow the weight of the airship’s structure to be significantly reduced, increasing the payload fraction. All the current interest in hydrogen as a power source and the “hydrogen economy” will require new designs for pipes and containers to safely contain and transport hydrogen on a large scale. Perhaps those technologies will make hydrogen airships safe enough to be viable, especially if people become used to using hydrogen as an everyday fuel. But that’s a lot of “might” and “perhaps”.

Now that’s an idea: produce hydrogen decentrally from water and solar, pump it into drone airships, and fly them to collection points.

There is an excellent history of the R101: “Fatal Flight: The True Story of Britain’s Last Great Airship” by Bill Hammack. Links to purchase at the author’s website http://engineerguy.com/airship/

The audiobook version is free! Search in your podcast player for “Fatal Flight” or use this url: http://feeds.feedburner.com/FatalFlight

I was struck by how similar the errors in the R101 project of 90 years ago are to the more recent ones so well presented by Sylvia.

Oh! I have this and it looks really good… but I haven’t yet read it. I really should have before diving into the Airlander incident.

Maybe I should put together a post of good aviation reads available free online and then we all take a week off and read them.

As a long-time reader of this fascinating blog, I’m very excited that I can actually contribute some information.

The author Nevil Shute’s (real name Nevil Shute Norway) original job was as an aircraft designer and he was deputy and then Chief Engineer at Cardington on the R100: the privately-financed competitor to the government-financed R101.

He is very scathing about the R101 engineering In his 1954 autobiography ‘Slide Rule’ and pretty-well blames the designers for the accident only holding off on a full accusation out of respect for their death in the crash.

His description of solving the unknown problems in designing an airship on a limited budget and difficult conditions along with his subsequent involvement setting up an aircraft construction company – Airspeed Ltd – make an interesting and fascinating read.

Thank you for this! That is interesting background.