Going Around: Bulgaria Air Charter flight 8115

It was 4am on the 16th of July 2018 when the Bulgaria Air Charter flight crew arrived at the airport, an hour before the scheduled 05:12 flight 8115 from Catania Airport (LICC) in Italy to Tarbes-Lourdes-Pyrénées Airport (LFBT) in France.

The aircraft was a McDonnell Douglas MD-823 registration LZ-LDM. The MD-80 series is a mid-range airliner easily recognisable by its low, arrow-shaped wings, rear-mounted engines and T-shaped tail. It was designed as a second generation DC-9 and in fact the first MD-80 was referred to as the DC-9-80. The MD-80 series was designed with a longer (“stretched”) fuselage, larger wings and more efficient engines: two turbofan engines mounted to the rear fuselage. With a higher maximum take-off weight, longer range and higher fuel capacity, the five-abreast coach seating made it a great choice for frequent, short-haul flights, allowing McDonnell Douglas to compete with the Boeing 737 Classic and the Airbus A320.

The crew that day was standard: captain, first officer and four cabin crew. The flight crew agreed that the first officer would be Pilot Flying and the captain as Pilot Monitoring (shown in the report as “Pilot Not Flying”). As the Pilot Flying, the first officer prepared the cockpit and the Flight Management System while the Captain did the exterior check and monitored the loading of the luggage. The passengers boarded on time.

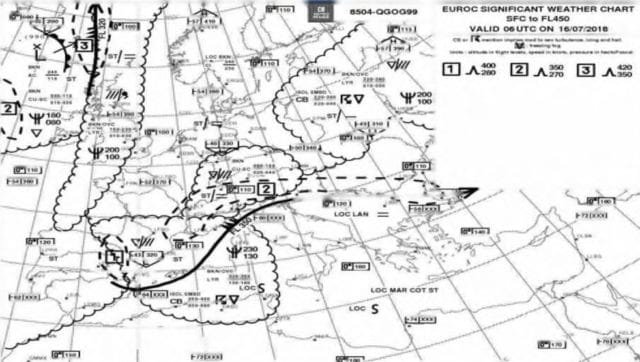

The weather at Catania airport was poor, with intermittent low clouds, thunderstorms and rain. The METAR (Meteorological Terminal Air Report) for their destination of Tarbes-Lourdes-Pyrénées Airport showed light rain and showers in the area, with low clouds and winds of 15 knots gusting 25; however, the forecast for their arrival in two hours included thunderstorms and rain. They would need to check the weather again as they approached the airfield.

The flight was routine as they departed Catania and climbed to their cruising altitude of FL330 (33,000 feet). As they flew through the Barcelona region, shortly before starting their descent, the flight encountered cumulonimbus activity, dense, towering vertical clouds which mark severe weather, lightning, hail, high winds and turbulent updraughts which can fling an airliner through the air like a lightweight toy. The flight crew deviated around the cloud system as they began their descent.

The weather at Tarbes-Lourdes-Pyrénées Airport was described as “complicated”.

Precipitation is intensifying in the Southern part of the country. There have been reports of thunderstorms in the Tarbes area with peak values at flight level FL350. The wind power at FL50 flight level is heading north at a speed of about 5kts. It should be noted that account is not taken of the possible gusts of wind in the information.

The map showed thunderstorms with maximum values between 35,000 and 40,000 feet, which implies more advanced and more intense storms. The airfield reported unstable winds and heavy rain with a surface wind varying between 100° and 260°. Lightning lit the skies, with three lightning strikes directly over the airfield. The rain was coming down at an average of 60mm an hour, with 78mm/hour for about twenty minutes. For context, “heavy rain” is defined as 4mm/hour with 50mm/hour described as “violent showers”.

The METAR for the airfield was as follows:

METAR LFBT 160700Z 25007KT 220V290 9000 RA VCTS FEW011/// SCT034/// BKN045/// ///CB 17/16 Q1018 TEMPO 28020G40KT 1300 TSRA BKN007 BKN040CB=

Rain and thunderstorms, with layers of broken clouds from 4,500 feet down to 700 feet. The wind was still shown as 20 knots at 280° with gusts up to 40 knots.

The air traffic controller at Toulouse Coordination agreed to assign the aircraft a lower flight level, offering them FL80 to the waypoint TEPTI. As they reached the waypoint, the Tarbes-Lourdes-Pyrénées approach controller asked the flight to descend following the ILS (instrument landing system) for approach procedure Zulu for runway 20.

The captain, in his role as pilot monitoring, asked for “confirmation of the permission” and the latest weather conditions. The approach controller offered the latest information: visibility 5km with rain storms, clouds few at 1,900 feet, scattered at 2,500 feet and overcast at 4,300 feet. The flight crew acknowledged the weather and asked about the latest wind direction, which was reported at 190° at eight knots.

The approach controller asked the flight crew to confirm that the aircraft was deviating to avoid the cumulonimbus activity, which the captain confirmed, saying they would maintain course 290° for another five nautical miles.

The flight experienced moderate turbulence and strong icing conditions as they descended through icing conditions to FL100 (10,000 feet). As the aircraft broke free of the dense clouds, the flight crew began the final preparations and briefings for the landing.

The slats and flaps were extended to 11°. The aircraft maintained FL80 for about 40 seconds and then continued to descend following the ILS approach Zulu.

They were able to see the ground through the scattered clouds and as the first officer turned left to intercept the ILS for runway 20, they had visual contact with the runway which was maintained throughout the approach. As the aircraft descended with a course of 204°, the flight crew reported intercepting the ILS for runway 20. The approach was stabilised as they descended to 500 feet. The first officer, as pilot flying, switched off the autopilot to continue the approach manually. Up until this point, the flight was normal and in full compliance with the airline’s standard operating procedures.

The landing gear, flaps and slats were extended. Approach asked the flight crew to change frequency to Tower.

The flight crew reported full interception of the ILS. The Tower controller asked them to confirm reading four nautical miles from the runway and gave the latest runway information: wind at 200°/10 knots, runway wet.

The aircraft was fully configured for landing in a stabilised approach at 2,200 feet above mean sea level with a calibrated airspeed of 140 knots. The airfield elevation is 1,259 feet above sea level. The autopilot was on and the auto-throttle was engaged in SPEED mode.

The auto-throttle allows the Pilot Flying to control the power generated by the engines by specifying the effect that they want, rather than a specific level of thrust. In THRUST mode, for example during take-off, the auto-throttle maintains a high power setting to allow for the aircraft to climb while increasing speed. If the auto-throttle is in THRUST mode, the aircraft speed is controlled by pitch.

In SPEED mode, a target speed is set and the auto-throttle maintains the power needed to achieve and maintain that speed. If the aircraft configuration changes, the auto throttle will automatically adjust the power in order to maintain the speed selected.

At this point, the aircraft was perfectly positioned for its landing on runway 20.

The first officer, as Pilot Flying, disengaged the autopilot with the auto-throttle in SPEED mode set for 140 knots. As he began manually flying the aircraft, the flight encountered strong gusting winds and heavy rain and the flight was blown off course. The first officer struggled to main control but the aircraft lost height as it deviated to the left.

The captain immediately took control of the aircraft and attempted to correct their course by banking to the right. At 250 feet above the ground, the aircraft began to sink below the glideslope. The Captain, having taken over as Pilot Flying, raised the nose to correct the loss of height but the auto-thrust, still in SPEED mode, struggled to maintain 140 knots after the pitch had increased. The aircraft continued to gently sink under the glideslope.

The aircraft continued to lose height. At 80 feet above the ground, the Captain pitched up aggressively as he shut down the autothrottle. He managed to halt the MD-80’s descent at 46 feet above the ground, still 460 meters from the runway threshold but now the aircraft was starting to drift to the right.

It continued level for about ten seconds as the speed dropped from 136 to 128 knots. The aircraft crossed the threshold of runway 20 at 37 feet over the ground with a heading of 196° and a calibrated airspeed of 129 knots, positioned just to the right of the centre-line. The captain attempted to bank left to line up with the runway; however at no point had he actually increased the engine power.

The first officer, described by the report as “extremely concerned”, shouted out to go around. About five seconds later, having travelled a further 350 metres (1,150 feet) along the runway, the captain called out GO AROUND and began to pitch up. He pressed the TO/GA (Take-Off/Go-Around) button, which helps to quickly configure the aircraft for climbing away from t he runway and started to follow the flight director arrows for the go-around.

However, he had forgotten or somehow not noticed that the auto-throttle was off. He did not make any power adjustments as he began to climb away.

By now, the MD-80 had travelled 830 metres (2,700 feet) from the moment when the captain disconnected the auto-throttle (at 40 feet above terrain and 480 metres before the threshold) to the point where he called for a go-around. Throughout this, the aircraft was close to the critical level of attack with the engines set just above idle.

I’ve been focused on the captain but the first officer, having taken the role of Pilot Monitoring, also did not ever check the position of the throttle controls or notice the deteriorating speed. Even after the captain called for a go-around, the first officer didn’t check or better yet, adjust the engine throttles for go-around power.

The MD-80 series aircraft has slightly different aerodynamic characteristics as a result of the engines at the back and the T-shaped tail. The engines set on the rear meant that the air flow would tear off later than in an aircraft with engines installed under the wing, as a result of the cleaner surface. In this situation, with critical angles of attack at low power, the aerodynamics of the aircraft is a key reason why they managed to stay in the air.

However, the T-shaped tail means that the tail panels can be affected by wake from the wing at high angles of attack, which quickly leads to a deep stall. The report recreated the situation:

The deep stall is characterized by two consecutive, energetic pitch-ups – two energetic pitches that ultimately lead to uncontrollable aircraft in the second pitch-up. At both the pitch-ups, the aerodynamic focus of the airplane moves and the airplane decreased, partially recovered for a short time, and then decreased again and completely lost its longitudinal stability.

Basically, when the aircraft first pitches up with a pitch angle of about 20°, the flow wake is spread across the wing and the aircraft can still be controlled. With “extreme and vigorous rudder commands”, the aircraft can continue to fly horizontally for a short time without sinking. Then a second pitch-up occurs as the horizontal stabiliser, which is already in a highly disturbed flow, stops having any effect and the aircraft goes into a deep stall which would not be recoverable from at low height.

At sixty-six feet above the ground, the captain called out for flaps. The first officer retracted the flaps from 40° to 11° in a single motion, followed by retracting the landing gear, setting the go-around altitude and selecting a target speed of 180 knots.

Although he had not increased the engine power, the aircraft’s height above the ground increased from 33 feet to 107 feet. The first officer reported “positive rate” (of climb).

His rapid retraction of the flaps had reduced the drag. The slats were partially retracted at the same time, which increased the angle of attack and allowed the aircraft to continue forward in horizontal flight. This caused the drag to increase again. There was not enough thrust to compensate and the MD-80 reached the critical angle of attack, with the wake almost all over the wing, although it did not exceed it, as shown by the aircraft rising (I hesitate to use the word “climbing”) to 107 feet.

The landing gear took about six seconds to retract, by which time the aircraft was travelling 116 knots and was pitched nose-up to 15°.

As the aircraft sank to 50 feet above the ground, the first officer disarmed the spoilers and suddenly noticed that the throttles were not in the correct position for a go-around. He asked the captain if he had put the engines into TO/GA mode. The captain told him to push the throttle forward — this was clearly not a good time for discussion. The first officer aggressively pushed the throttle controls forward to the maximum position.

By now, the pitch had reached 19.8° with an angle of attack was 38.6° and their speed had dropped to 116 knots at 49 feet above the ground. The aircraft had travelled another 850 metres along the runway, meaning that it had travelled a total of 1,680 metres (5,500 feet) at a critical angle of attack.

The full length of the runway was 2,993 metres (9,821 feet).

The parameters of both engines quickly reached maximum values. The captain quickly intervened and corrected the engine power to the TO/GA setting.

Once they’d achieved 342 feet above the ground at an airspeed of 141 knots, he reduced the engine throttles to normal climb and banked left for a course of 080°. The final stage of flaps was retracted, the auto-throttle was engaged and the auto-pilot turned on. The flight crew performed a holding pattern and agreed to divert to their alternate airport. The flight landed at Toulouse and then returned to Tarbes-Lourdes-Pyrénées Airport a few hours later, once the weather had cleared.

The captain did not consider it necessary to report the incident to his management. However, the controllers on duty absolutely did consider it necessary to escalate the issue, reporting that those on shift were “terrified” by the approach and had been expecting the plane to crash at any moment. The dispatcher filed a written report which described the incident in detail.

One A/C MD82 of a Bulgarian company was performing an ILS approach for RW 20 around 09:30 AM, local time. The weather was stormy, very rainy, but the wind was weak. Given the meteorological conditions, we expected the plane, we expected to see it coming out of the cloud layer, and finally, we saw its lights being too low and too far. Thus, the plane would land at about 500 m before the threshold of the runway and to the extreme left of the runway (probably wind shear). The plane tried to return to the RWY axis, and its wings were low, over the threshold of the Runway, it retracted the landing gear to make a Go-Around.

Then the plane quickly came with a high pitch in [an] attempt to climb, but the speed was low. The aircraft flew over the entire runway with abnormal high pitch, with a tail at 20 m from the ground, unable to climb and even lost some altitude. Total horror, we almost saw the plane collapsing at the end of the runway, with the same configuration as Airbus in Hamsheim. Then, at the end of the runway, and with this high pitch, it managed slowly to climb, flew very close to a hill, turned left, and was radar vectored to head North again. The plane then went to Toulouse, where it landed and in a few hours returned to us again.

The local Flight Safety Unit immediately prepared an official report for the French aviation investigation bureau, the Bureau d’Enquêtes et d’Analyses pour la Sécurité de l’Aviation Civile (BEA). The BEA classified the case as a serious incident and passed it to the Bulgarian Aircraft Accident Investigation Unit (AAIU).

The cockpit voice recorder had been overwritten as the flight crew had not made any report and had not removed it. However, the aircraft’s digital flight data recorder confirmed the sequence of events as described by the controllers.

The report concludes with a probable cause of “pilot mistakes”.

4.2. Causes

On the grounds of the analysis made the Commission points out that the serious accident is the result of the following cause:

Pilots mistakes in crew coordination and in-flight technology in bad weather conditions during the landing approach and the go-around procedures at the Tarbes-Lourdes-Pyrénées Airport, France.

*Safety Recommendations*

Taking into account the causes of the serious incident and the deficiencies found in the investigation, the Commission recommends that the following measures should be taken to ensure the flight safety:

* BG.SIA-2018/08/01. AO “Bulgarian Air Charter” must organize and carry out additional theoretical CRM training course, and the A/C crewmembers, who have caused the serious incident, must undergo a flight simulator check.

* BG.SIA-2018/08/02. During the next flight simulator training session, all MD-82 pilots of AO “Bulgarian Air Charter” to include an exercise with similar conditions for flight performance as in the case of the serious incident.

You can read the full report on the AAIB site.

This incident was also covered by AVHerald and I was deeply amused by this comment by “The Wrench”:

I’m just surprised the report doesn’t say anything about the hand of god reaching down from the clouds to hold the little airplane airborne until the mortals within got their s**t together.

Well, it was Lourdes, after all.

I would have liked to have seen more about the Cockpit Resource Management but I suppose without the CVR, it is hard to do a real analysis of the crew actions and interactions. The investigators also clearly struggled when writing a section about the decisions which saved the incident from becoming a fatal accident. The crew were flying thirty-three feet above the ground, travelling 116 knots with a pitch of 20° and no power, hoping to go around. It’s hard to work out how, having ended up in this position, one could highlight how their final choices may have increased the chances of survival.

The controllers were right to be horrified and that captain may not have had an ounce of CRM but he kept that MD-80 flying along the entire length of the runway. If I’m honest, that must have been one hell of a slow and low flight to watch.

I’ve read a recent update on another site that focuses on planes touching the water short of the runway, and it contains this gem of advice: “One of the benefits of the stable approach is that once you’ve got the airplane aimed to the touchdown point, the next move should be to reduce power and flare. If you find yourself doing something other than that prior to getting to the flare, you’ve done something wrong and a go around is well advised.” As was the case here.

Being an “armchair pilot” with a good flight simulator setup, I can confirm that in the most difficult of landings (F/A 18E carrier traps) you can adjust height and speed fairly easily provided you are high and fast. Lineup is a deal breaker. If you see you are not lined up and need major corrections – gear up and TOGA power. My rules are – Don’t be low and don’t be slow and nail that centreline. Plus – Quit while you can. This flight flirted with all these tenets. “Hand of God” indeed.

Sylvia puts a lot of emphasis on the aerodynamics of the DC-9 when she describes the “deep stall”. This was first identified during the flight testing of the BAC 1-11 when the prototype crashed during stall tests. It resulted in the installation of “stick shakers” and “stick pushers” in jet transport aircraft. All relevant data were passed on to Douglas who were in the process of introducing the DC-9. The investigations set back the certification process of the 1-11 and it lost its lead position to McDonnell-Douglas, a set-back from which it never really recovered (although the 1-11 was the better aircraft).

What she is omitting may well be an important piece of the puzzle: The ages and experience level of the cocpit crew members.

Thunderstorm activity in the proximity of an airport is a known cause of so-called “microbursts”. Small cells of violently moving up-and downdrafts can have a very serious effect on the ability of an (any) aircraft to follow a stabilised approach. An updraft, causing the aircraft to commence an undesired climb, is counteracted by the autopilot and autothrottle systems to pitch down and reduce power. This, in turn, can cause another upset when the aircraft encounters an equally violent downdraft, which requires an aggressive pitch-up and application of maximum power to counter the sudden and sometimes rapid loss of altitude. Most if not all flight training centres have microburst training incorporated in the simulator sessions.

Even though this flight did not seem to have encountered a microburst, it would seem plausible that the aircraft at least was affected by some downdrafts and windshear caused by the thunderstorms. Strong enough for a textbook stablized approach to become unstable.

In a situation like this, when the captain suddenly takes over as “PF”, it can quite easily destroy any form of CRM. A F/O, from being the “PF”, suddenly has to make the switch to being “PNF” and becoming the monitoring pilot. This all happened quite close to the ground, obviously the F/O was not expecting this role change and did not adapt very quickly. It might have been better if the captain had just commanded a “go-around” without taking over. “Might”, yes, it is easy to be wise after the event. But the story – fortunately with a happy ending – seems to point to a captain with limited experience; the co-pilot does not come across as being highly proficient either.

Trying to cover up an incident as serious as this one surely must be a career-ending event.

I’m not sure why I skipped the crew information! I definitely should have included it.

Captain held an ATPA with type ratings for DC9, MD80, 88 and 90 with 24,200 flight hours and 6,100 on type (as PIC).

First officer held commercial license with 2,000 flight hours and 1,200 on type.

Both were assumed to have the necessary training, qualifications and duties. There was no reason to consider fatigue based on their roster and flight times.

This suggests that controllers should be able to report incidents quickly (at least in summary — details could follow), so that removal or downloading of black-box data doesn’t depend on the crew. I get that this would not be welcomed by pilots, but IIRC this is the second recent article in which data should have been copied as soon as the aircraft landed.

Rudy’s analysis brings to mind the phrase “changing horses in midstream”, although I also wonder whether the captain should have called for a go-around earlier. Should the airline have been more careful about making sure that at least one member of the cockpit crew had enough experience to be able to make quick decisions correctly? (IIRC we’ve discussed poor pairings of pilots in other threads.) Or would this have been the best staff a small charter airline could come up with? (ISTM they were certainly economizing by using an aircraft that had been out of production for a couple of decades.)

wrt the BAC 1-11: Wikipedia says that half the original production went to the US (no discussion of delays in the original version due to handling problems) but that production of a larger version was delayed because BEA (the largest single buyer) dithered over whether it wanted bigger aircraft, while the DC-9 went straight on to stretched versions. They’d welcome citations for delays in the original production. I rode in a 1-11 in the late 1970’s and don’t remember it feeling any different in the passenger section, but it may have been the smallest plane I’ve ever ridden in that was certified as a full-size airliner rather than a “commuter” plane.

Chip,

I still have a problem allowing the press to name aircraft parts. They had a habit in the past of writing about aviation – mainly acidents – without much, or even any real knowledge, it just had to be sensational. The “black box” is bright orange coloured with reflective material. This reflects not the colour, but the ignorance of the press! Flight data recordings are never downloaded by the crew. If an incident occurs they are by law obliged to stop the cockpit voice recordings so that the recordings at the time of the incident are not overwritten. The old systems used 30 minute tapes, I can imagine that newer technology in fact allows longer periods.

Sylvia’s blog makes no mention of the experience- or competence level of the crew.

Reading this article, it seems that it is quite possible that thunderstorm activities in the vicinity could have caused the approach to become unstable. Obviously, at a late moment, the captain decided that the first officer was not up to the task. At that same moment he should have made the decision to either “get back in the groove”, or go-around. Taking over the controls certainly suggests that the circumstances would have mandated the latter action. The CRM fell apart at that moment, as far as I can see.

The incident was reported by the air traffic tower controller who was horrified to see the MD80 skim just above the runway. But if you ever have been in a busy air traffice control room or -tower you will realise that, strange as it may seem, the staff do not always have time to constantly monitor what is going on outside. Yes, they do take regular “peeks”, but strictly speaking they are busy controlling the stream of arrivals and departures. This requires constant and intensive R/T communications which may take precedence over a continuous looking-out. ATC centres do not even need to be at an airport.

The BAC 1-11 was developed before its rival the DC-9.

It did not have handling problems; the “deep stall”, is a condition described by Sylvia. In simple terms: When the aircraft stalls, the T-tail gets in disturbed airflow from the wings, making the elevators ineffective. The aircraft cannot recover and crashes. This had not yet been a known phenomenon when tests with prototypes involved stalling the aircraft. The test pilots continued to radio their actions to the base right up to the point of impact. This allowed British Aircraft Corporation to analyse the cause. Following tests were done with a vertical JATO rocket mounted in the tail. When the aircraft again entered a deep stall, the rocket was fired. This forced the tail up and the aircraft recovered.

This delayed the introduction of the 1-11. The data were made available to all manufacturers. Using the 1-11 data about the “deep stall”, Douglas was able to “pip BAC to the post”. Yes, the 1-11 was sold in numbers to the USA.

The original 100 and 200 series were small, but so was the DC-9.

The version I flew was the stretched 500 series with a capacity of 114 passengers, up from 70 in the 200.

Handling problems? Not that I am aware of, although the -500 was more prone to “firm” landings than the shorter versions.

Because of its very solid built it was also a bit heavier than the corresponding DC / MD aircraft. These were fitted with P&W engines, the 1-11 with RR Spey. The 1-11 airframe had no time limit and there were serious proposals in the ‘nineties to upgrade them with glass cockpits and RR Tay engines. At the time it was estimated that the life of the aircraft could have been extended by another 20 years. Of course, this was not to the liking of the industry, they preferred to sell new aircraft. I believe that one or two corporate owned 1-11 had been converted.

Which was the better aircraft? The 1-11 was built like the proverbial “brick sh..t house”. It was also a bit heavier than the rival. Not such a problem then, but with rising fuel cost this became an issue.

I left Ryanair before the B737 replaced the 1-11, but I remember it fondly.

I had thought about microbursts in the context of that advice, and I feel that if you’re not prepared for them, you’d better go around. And that in this case, they’d have been better of with the FO flying the go-around, and the captain setting up his own approach: the awareness of the state of the plane (throttles!) must be better when you’ve done the whole thing yourself.

The FAA certification for the BAC 1-11 was Nov 22nd 1965, the DC-9 was certified the next day. Given that the 1-11 first flew in August 1963 when the DC-9 development began in July 1963 on the drawing boards, Douglas definitely profited from that delay.

There is an excellent account of the discovery of the deep stall on the BAC 1-11 at http://www.bac1-11jet.co.uk/bac1-11jet.co.uk%20Mike%20Lithgow.htm .

I agree except that I’m not sure “cavalry charge” for a triple beep is any less sensationalistic. :D

Rudy: I’m quite aware that aircraft “black boxes” are orange, just as DEC’s Little Blue Thingies were later red. (You may not have seen these; they were used to secure DECtapes, ~pocket-sized reels that were a conceptual predecessor of the floppy disk and the thumb drive.) “Black box” is an engineering term for a device that takes input and gives output without the user being concerned with the mechanism; it’s quite possible the term was first applied by technicians rather than the press, before somebody realized that an orange outside would be a Good Thing. Wikipedia reports that CVRs have had 2-hour recording for some time.

I have been in busy control rooms. Part of my training for both private and instrument licenses was a visit to the KBOS tower (which I think I’ve mentioned). The instrument rating also involved visits to KBOS local control and the en-route control center for New England (except near New York City), which is an hour north of Boston. IIRC Ketchikan (subject of a previous column) had no local controller when I flew a scheduled service out of it in 2000. (We were told that we were leaving in a hurry because an inbound was about to slip out of regional’s view.).

However, none of this means there should not be reporting where it is possible. I very specifically did not suggest REQUIRING controllers who saw something to say something; I suggested that they should be ABLE to report incidents quickly enough to make sure that recorders get read out before they’re overwritten. LFBT (again per Wikipedia) had less than half a million passengers in 2018, so the controllers would probably have had time to call in a download-the-data order once it had gotten this crew sorted and on its way to an airport they could land at.

Mendel: thanks for the hard data. It looks like the original BAC 1-11 was still running even with the DC-9 (in the US — how did they stand in Europe?) after sorting its issues, and could have continued to do well if not for the BEA-related delay on extended models (which tend to be most of an aircraft’s production).

Chip,

Perhaps I have been guilty of being a bit vague. Blame it on my habit to write without referencing.

I never heard of DEC’s “little blue thingies”. But of course, I was flying one of their two King Air 200s, later the Citation 550 (N121C).

To the best of my knowledge the FDR was never “black”. I believe that the recordings on the first ones were inscribed, chiseled, in a metal tape for fire protection. After a certain amiunt of flying the tape would be excahnged. And it is not impossible that engineers were referring to boxes containing electronic gizmos as “black boxes”. But the press fraternity, especially in earlier days, were certainly not bothered by any lack of factual knowledge when it came to dishing up a sensational story of an air crash. That, more than the misnomer “black” for an orange object, is actually the real reason why I am so much in arms about it.

I may have been mistaken about the duration of the CVR, 30 minutes does seem to be a bit short. But the idea behind it was to have a recording of a certain time period before an accident – when presumably it would have stopped anyway. If a reportable incident occurs the crfew are supposed, nay obliged, to stop the recording so that the taped recording of the last period leading up to the incident will not be overwritten.

I absolutely agree with you that controllers also have a duty to report an incident if they are aware that one has taken place. A usual set-up is that the tower controls the movements at and around the airport, with or without a separate ground control operator. The latter often have cameras to see what is going on at parts of the airport that cannot be adequately monitored by looking out, and increasingly also have ground radar at their disposal. The tower controls the aircraft taking off, landing as well as traffic in the control zone. Approach control has been assigned mainly IFR traffic, yes, in an approach including the STAR. There may also be a departure controller taking care of the SID.

The tower controllers have the best view from their glass-covered loft.

Approach and departure may be situated in a separate room below the glasshouse.

And the airways, aircraft climbing or descending or cruising are the responsibility of control centres that more often than not are located off the airport, e.g. Eurocontrol in Maastricht, the Netherlands, Prestwick, Shannon to name but a few.

The staff operating the tower of course do look out, but they may be busy with their tasks and miss something. But an MD80 making an extremely low pass with the nose at a high angle must have attracted the attention of someone. They would have been expecting questions referring to this incident, following the captain’s report. My guess is that, when no such request came, they themselves – quite correctly – sent their report. Having seen the incident and anticipating questions there can be no doubt that they would have written their version of events as, and as soon after when they witnessed it.

The BAC 1-11 was last produced under licence in Romania in the late 1980s. They were known as the RomBAC 1-11. After completion they were flown to a BAC facility at Bournemouth where they were examined to ensure conformity as well as quality. These were the 500 series, Ryanair operated RomBac aircraft, leased from Romania. The contract stipulated that at least one Romanian crew was to be based in Dublin per aircraft. This to ensure that crews would be around to repatriate them to Romania if Ryanair were to default on the bills. There also were Romanian mechanics alongside their Irish counterparts to maintain them. It worked well, except the Romanian pilots who were always teamed together were chain smokers. The aircraft were not old, perhaps 3 or 4 years but the cockpits reeked of cigarette smoke and everything we touched was grimy from smoke residue.

The airframes were nearly indestructable but the Spey engines were noisy. We would fly to the noise monitoring points in the SID, indicated by a circle with black and white segments; just before the monitoring point we would pull the power back to flight idle, then sail – whispered – past it and then bring the power back up to maximum climb, nose up, last segment of flaps retracted and another complaint avoided.

There was an article in a British aviation magazine in which the conversion of the 1-11 was discussed – even recommended. I remember that the conclusion was that with RR Tay engines and a revamped cockpit the lifespan could be extended to the point where a young pilot, just from the flying academy and starting his or her career with a 1-11 operator, assuming that they would not be assigned to another type, could reach retirement still flying the 1-11.

It never happened of course. The 146 was promoted, there was a change in the British aircraft industry with mergers and new alignments.

Apart from Rombac being a non-EU manufacturer, the aviation industry changed. The airlines demanded more fuel efficiency, the public more comfort and Boeing as well as Airbus were able to deliver the goods.

Rolls-Royce had gone through a bad patch and concentrated on the RB211. Once pround names: De Havilland, Vickers, Bristol, Scottish, they lost their independent status as aircraft manufacturers and became secondary suppliers.

“The parameters of both engines quickly reached maximum values. The captain quickly intervened and corrected the engine power to the TO/GA setting.”

All right, I’m curious. On an MD-80, very low, very slow, very high nose – what would be the difference between maximum power and TO/GA setting? Seems to me you’d want all the power you could get.

I’d have to guess that the engines really aren’t rated for max power for any length of time – it’s an emergency thing? Or jets at low airspeed don’t like wide-open throttle? I dunno. J.

Rudy — “They would have been expecting questions referring to this incident, following the captain’s report.” That’s entirely plausible — and the part that I’m thinking should be changed, so that everyone can be alerted to grab data before it gets overwritten, the next time a flight crew has a near miss but decides it’s no big thing. Possibly such … insouciance … seems too rare to be worth providing for.

Amusing to hear that 1-11 production was sent to Romania — a bit like Volkswagen Beetles being produced in Mexico during the hiatus in German production (although the Mexican ones didn’t meet all international standards). My sympathies on the fouled cockpits; I left a computer job in 1987 partly because the “indispensable” chief engineer was a heavy smoker (who left ashes anywhere, including on the machines I was supporting), and have unpleasant memories of being accosted by a fellow-passenger who I’d dimed for smoking in the no-smoking zone (rows ahead of me, so I was getting their exhaust) in 1985. I was surprised to find ( https://en.wikipedia.org/wiki/Inflight_smoking ) that cockpit crews in the US were still allowed to smoke after the 1990 cabin ban — apparently the FAA worried about flight crew having nicotine fits. (This was after the nicotine patch was invented, but much — they may not have considered it sufficiently tested to substitute.)

Jon,

Maximum power of jet engines is related to the density altitude. On older aircraft we had to extract an “EPR” (engine pressure ratio) setting and we set it with a movable index on the gauges.

More modern engines are electronically controlled, but that also has the disadvantage that the crew willneed to override the electronics in case of an emergency or unusual situation.

On the older Cessna Citations we would have a table for the take-off power setting, based on the fan speed. this might be (random example) 99%. The fan speed was allowed to increase with altitude and, sounds strange, could go as high as 102% on the -500, even 104.1% on the -550. Yes, I know more than 100%. Presumably based on the earlier engines where 100% would have represented the maximum and increased to more than 100% on later, more powerful developments.

The P&W JT15D engines of the (now old) Cessna Citation were not electronically controlled. During climb the N1 would creep up and we had to constantly monitor and adjust the power.

Chip: It is not really all that long ago when it was accepted that no-smokers had to put up with the habit of others who did smoke. We had a rotation from Bahrain and positioned via Istanbul. For some reason there were always many Russians on board who refused to stop smoking, even in the no-smoking section and even when the crew told them to extinguish their cigarettes. They simply gave up.

For those interested in the “deep stall”: My son found a video of tests on the Fokker F70. The test pilots talk in Dutch. “trekken” means “pull”.

Watch https://www.youtube.com/watch?v=FzUakyCFYSc

I guess you mean “Jet throttle settings depend upon air density, and you can push them further forwards in search of more power in thinner air”. Also “Don’t do that in thick air, because it’s bad for the engine”. Or something like that?

I don’t know if MD-80 engines are electronically controlled. I imagine they are, if with somewhat more primitive electronics than you’d expect on, say, a 737MAX.

I have no idea what “N1” is.

Two asides: One of the last messages from the Challenger space shuttle was that they had set their engines for 105% power. And it was (partly) my father’s research that showed just how nonsensical the “Smoking” area on airliners was, and how horrible smoking on jetliners was for everyone involved, leading to the total ban.

Thanks for getting back to me, J.