Airline In Sweden Has No Plan For Snow

On the 31st of January in 2014, an Estonian aircraft registration ES-PJR ran off the side of the runway at Torsby airport in Sweden.

The aircraft was a BAe Jetstream 3200 (J32), a low-wing twin turboprop aircraft popular for small passenger services. The J32 seats up to 19 passengers.

The J32 was operated by AS Avies, an Estonian airline offering both cargo and commercial passenger flights. AS Avies worked as a sub-contractor to a Swedish operator who held the contract to run services between Torsby and Stockholm.

AS Avies held a valid operating licence and AOC issued by Lennuamet, the Estonian Civil Aviation Authority.

That day, the schedule was to fly from Stockholm to Torsby in Värmland. Then, after refuelling, the aircraft would continue to the operator’s base in Tallinn, Estonia.

However, Stockholm was suffering from heavy snowfall. After the aircraft was de-iced, it was held for a further half an hour on the taxiway while waiting for the runway to be cleared of snow.

The flight from Stockholm, with two crew and fifteen passengers on board, finally departed an hour after its scheduled departure time. However, the weather at Torsby was no better and the crew received warnings of severe icing along their route.

Icing conditions are when water freezes on impact with the external structure of the aircraft during flight. Atmospheric water exists in liquid form well below freezing. This supercooled water forms droplets which can strike the surface of the aircraft. When an airframe collects ice, the aircraft performance is reduced. The icing can lead to a change in the control ability of the aircraft, as the structure has been changed, as well as a loss of lift, causing a stall and loss of control of the aircraft. In addition, ice can form along the air inlet path of the engines. If the engine inlet path becomes blocked, the engine will fail.

The captain was not concerned by the warnings of severe icing on his route, conditions under which many flights are cancelled, as he understood that the BAe Jetstream 32 was approved for flight in all ice conditions, thus he felt there was no issue with severe icing.

He planned the flight with two alternate airports in case it was not possible to land in Torsby. The fuel on board was the minimum permitted fuel quantity for the flight. This allows for reaching the alternate airport after two missed approaches and then a further thirty minutes reserve.

The captain knew that the aircraft’s propeller de-icing system for the right engine was not working, although this defect was not noted in the aircraft logbook.

The flight proceeded normally. Although other flights in the area reported moderate to severe icing, the Jetstream appears to have only collected light icing during the flight.

As they approached Torsby, the visibility was 2,000 metres and the snow was still falling.

Here’s the view from the Torsby airport webcam today. You can click on the image to see the webcam with live updates.

Runway 16 at Torsby Airport is 1,590 metres (5,200 feet) of asphalt. The snow was falling continuously leading to what is called a “contaminated runway”. The airport staff check the runway condition by sending a vehicle to collect samples from the runway, so that they can measure the friction coefficients.

Friction coefficients is a way of calculating how slippery a surface is. The friction coefficient is directly proportional to the braking action that an aircraft can achieve when braking after landing.

This measurement basically gives a value to the friction between the aircraft tyres and the runway’s surface. A lower coefficient means that the aircraft will have a reduced braking ability. This means that the aircraft will require a longer distance to come to a halt.

The runway samples gave measured coefficients of 0.25, 0.25 and 0.23, which is marked as a rating of 1 out of 5 and correlates to ‘poor braking action’ in standard phraseology. The airport staff sent snow clearing vehicles to clear the runway in an attempt to improve conditions.

Nineteen minutes before the flight was due to land, the airport took new samples from the runway. This time, the coefficient results were 0.30, 0.31 and 0.33, rating a 3 out of 5 and corresponding to “medium braking action”. This information was passed to the aircraft which was still over 15 minutes away. The snow continued to fall.

There are regulations regarding operations on wet vs dry surfaces: the landing distance under conditions with a wet runway must be at least 115% of the required landing distance of the aircraft in dry conditions. However, there is no such rule specifying calculations for contaminated surfaces; it is up to the operator to determine the additional landing distance required if the aircraft is expected to operate on runways with contaminated surfaces. It must, however, be at least 115% of the required landing distance of the aircraft.

The snow-clearing vehicle cleared the runway as the aircraft turned for its approach, seven minutes before touchdown.

The flight crew acknowledged the information about the friction coefficients but did not change their planned approach. They had no information about the performance data of their aircraft on contaminated runways and they did not believe that there was anything they should do differently in reported conditions of “medium braking action”. So they did nothing.

The first officer was the Pilot Flying as the aircraft came in to Torsby. The runway lights were clearly visible as he flew in for a manual landing. The captain did not see any visible icing on the aircraft and so did not see a necessity to increase the VREF speed (the speed when passing over the runway threshold) by 10 knots as prescribed by the flight manual if there is ice on the aircraft.

In the final stage of the approach, the captain pointed out to his first officer that his speed was high: he was coming in too fast. He also noticed that the PAPI lights indicated that the aircraft was coming in low.

The first officer couldn’t remember if the wings were checked for ice during the approach; he was focused on flying the aircraft, which did not have an autopilot. He said he decided to maintain a somewhat higher speed during the approach although they’d not agreed a faster landing speed. Later, investigators found that the airspeed indicator on the first officers side showed a speed about 5 knots lower than the airspeed indicator on the captain’s side, causing a further discrepancy between the agreed VREF and the actual speed of the aircraft.

The first officer raised the nose to correct the pitch angle. At this late stage of the approach, the aircraft was travelling faster and lower than expected. The first officer’s last minute adjustment to the pitch was too abrupt: the overcorrection led the aircraft to come in over the runway threshold too high.

This is exactly why a go-around is executed if the approach is not stabilised. Most accidents of landing planes are preceded by an unstablised approach. If the speed and glide path angle are not as expected, the approach should be broken off and the aircraft should go around and try again.

It is the job of the Pilot Not Flying to declare whether the approach is stabilised. The captain considered the approach to be stabilised and that it was safe to continue.

The aircraft touched down on runway 16 at high speed. The first officer retarded the throttles to idle and initiated thrust reversal. They had 800 metres (2,625 feet) remaining runway length ahead of them. It didn’t look like it was going to be enough.

The captain took over the controls and started braking. He set the engine controls to full thrust reversal.

The aircraft continued to speed across the runway. The captain said that the surface was “very slippery”. They were not going to stop in time. The captain had to choose between running off the extension of the runway or attempt a high speed turn onto the taxiway.

The captain realised they were not going to stop in time and he attempted to turn right onto the taxiway. However, the aircraft was travelling too fast for the manoeuvre and he lost control during the turn. The aircraft veered off of the runway, running into the snow between the runway and the taxiway. It plowed into a snowdrift and came to a halt a few metres away from the taxiway.

The crew informed tower of the situation, shut off the engines and evacuated the passengers.

On the face of it, this was a minor incident. The aircraft came to a safe stop no one was injured and there was no damage to the aircraft. The Swedish investigation only had to answer one question: Why had the aircraft not been able to stop in time?

It soon became clear to the investigators that the answer was complicated. Not all was right with this flight.

First, there was the issue of the right-side propeller’s de-icing system not working. The decision to carry on into severe icing conditions despite this was not just foolhardy, it meant that the flight crew was not complying with the Minimum Equipment List, which defines the conditions under which an aircraft can still be operable when there are equipment failures.

The captain was aware that the de-icing systems were not working and he also knew that this was not noted in the log book, as required. However, he was equally adamant that there were no deviations from operational routines or regulations. Not on that flight and not at any other.

He considered the situation in Torsby to be normal winter weather and that the flight that day had no operational problems or limitations. He said that the BAe Jetstream 3200 had been designed to cope with a lot of ice and he had only had good experiences of flight under severe icing conditions.

Now, the J32 is a lovely little aircraft. It is designed and certified to be able to meet the requirements for operations in icing conditions, and the truth is, there’s no detail as to which icing conditions are appropriate. But generally speaking, even certified aircraft avoid severe icing conditions and in fact in the J32 Aircraft Flight Manual, there are clear warnings and instructions for crew in the case of encountering severe icing. Instructions that the captain knew nothing about.

More importantly, the Minimum Equipment List makes it clear that the aircraft can be flown without a serviceable propeller de-icing system but only if it is not operating in known or forecast icing conditions.

In the Swedish winter conditions, the aircraft should have been grounded as soon as that defect was clear.

The first officer also said that they did not experience anything out of the ordinary and believed that they only experienced light icing during the flight. He was not aware that the right-side propeller de-icing system was not working.

He couldn’t recall if the expression “stabilised approach” had been used to confirm that he should continue. In fact, he said that the concept of a stabilised approach was not one that they used in daily flying or in training.

He was sure, however, that there was no discussion regarding the landing conditions or the friction coefficients that had been reported. He said that they didn’t discuss this as there are no procedures to correct for contaminated surfaces, for example a runway covered in snow.

This is particularly disturbing as the airline’s routes in Sweden and Estonia meant that the airline crew must regularly encounter snow on the runway and icing conditions, yet they were not given even the most basic information for dealing with this.

The first officer was also right in that the airline didn’t have any definition for a stabilised approach, which should be used for flight crew to determine whether to continue the approach or break off and try again, especially in adverse weather conditions.

The investigation looked at the calculations regarding landing on Runway 16 under the conditions of the flight that day. The calculations were done with a friction co-efficient of 0.275, as the snow had continued to fall for 17 minutes after the previous measurement of just above 0.30.

So: the wind was variable at 3 knots, the aircraft was 7,059 kg (max 7,080), at a VREF speed of 125 knots (115 knots + 10 for icing, as per the aircraft flight manual) and a friction coefficient of 0.275.

On the basis of those values, the landing length required for the aircraft was 1,473 metres. As runway 16 is 1,590 metres, this would leave additional margin of 117 metres (380 feet).

However, the aircraft didn’t land on the numbers. From the point where it actually touched down, there were only 800 metres of runway remaining; no where near enough to stop the aircraft in time.

The investigators recovered the Cockpit Voice Recorder and the Flight Data Recorder from the aircraft.

The Cockpit Voice Recorder holds 30 minutes recorded conversation from the cockpit. In this instance, it consisted of telephone conversations between the captain and the operator’s technical department, which took place some time after the incident. When an aircraft is involved in a serious accident, for example, veering off the runway at high speed and plowing into a snow drift, the flight crew should cut the power supply to the cockpit voice recorder, in order to avoid overwriting the recording with new information. However, the crew didn’t do this and thus the recordings of the approach and the incident were lost.

The Flight Data Recorder holds 25 hours of data, recording the flight parameters using a microprocessor that converts, digitises and formats the data for later retrieval. When reading data from the FDR, the data values are relative. They are decoded into engineering units (for example knots or degrees) using a system specific to the installation in an individual aircraft. That is, you can’t just drag the FDR out of any old plane and plug it in and get the data. You need to know the details of how it was installed in order to convert the data into something useful.

The Flight Data Recorder held all the data from the flight in question but the operator didn’t have the documentation in order to convert the data. This means that the recorded parameters from the FDR weren’t reliable and attempts to read the data using generic conversation document led to parameters which were not representative. As a result, the data from the Flight Data Recorder cannnot be treated as definitive.

The worst of it was, both of these issues, the overwriting of the Cockpit Voice Recorder and the lack of documentation for the Flight Data Recorder, had come up in a previous incident in Sweden. The investigation had highlighted this at the time and the airline had been informed that these were regulatory issues that they must comply with. This wasn’t a one-off problem but a systemic failure to abide by regulations.

The airline had also previously had issues with aircraft faults not being logged in the technical log. The airline explained that they had their own system for this and did not use the technical log. Note: this is not something that an aviation operator can choose not to do. It is required.

But they didn’t do it. I would hate for you to think I am exaggerating for effect so here is the exact quote from the previous accident where this came up.

The operator has stated that the system works well in general and that there have only been a few instances of misunderstandings. The reason for the pilots being instructed not to write the technical remarks in the logbook is, according to the operator, that this entails a greater risk that the aircraft will be grounded.

Yes, that’s right. The pilots are not to report defects with the aircraft because it might mean that the aircraft is not deemed fit to fly.

This is exactly the bloody point.

The Swedish Accident Investigation Authority contacted the Estonian and Swedish aviation regulators during the investigation to highlight the compliance issues they were finding. The Estonian authority, as the issuer of the operator’s Air Operators Certificate, has the responsibility for the company. The Swedish Transport Authority cannot regulate the airline but can initiate safety inspections to verify the operator’s safety and quality for flights within Sweden.

The Swedish Transport Agency began conducting inspections of the airline, specifically focused on the flight crews’ performance calculations. They reported that the crew continued not to have any performance data for dealing with contaminated runways. They forwarded the report to Lennuamet, the Estonian Civil Aviation Authority, for immediate response to ensure that AS AVies used the correct data for performance calculations and if they did not, the Swedish authorities advised Lennuamet that they should limit or revoke the airline’s Air Operators Certificate.

Lennuamet responded to say that AS Avies had demonstrated the relevant performance calculations were being used by the airline for safe operations on contaminated take-off and landing runways.

The airline hired a consultant to draft a manual with performance data for the BAe Jetstream 31/32 including tables and correction data. The performance data manual was submitted to Lennuamet on 24 October 2014. It was approved the same day and distributed to the pilots for use.

However, the manual was hardly much of an improvement. Usually, such a manual will contain data on all of the airports that the operator flies to. In this case, only general calculation bases were produced, which meant that pilots had to manually enter in all the conditions for operations at an airport: runway lengths, slopes, height above sea level, etc, every time they wished to calculate the aircraft’s performance in winter conditions.

On the 6th of March 2015, the Swedish Transport Administration terminated the contract with AS Avies and opted not to sign agreements for another two routes which had been under discussion. The reasons given included the fact that the operator had by now already suffered four serious incidents in Sweden.

The cause analysis by the Swedish Accident Investigation Authority is extremely well written and worth quoting directly.

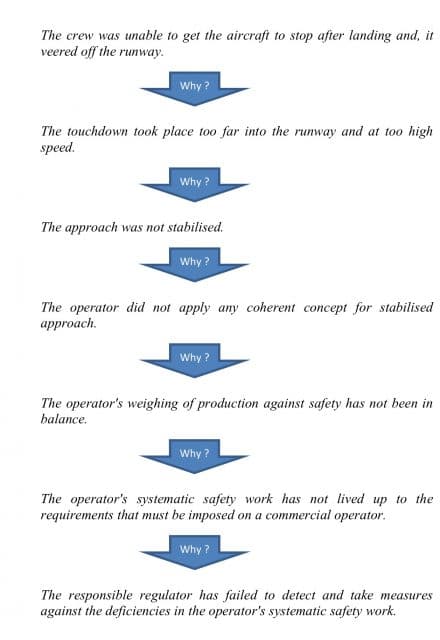

In this case, the direct cause of the aircraft running off the runway is simple to establish:

The touchdown took place too far into the runway and at too high speed.

However, this conclusion is inadequate as a thorough explanation of the incident and, even more so, as a basis for effective safety recommendations.

SHK has chose to to give a picture of the incident that occurred by means of the following description of cause.

In the final report, the Swedish Accident Investigation queried directly as to why Lennuamet aviation had not discovered the operator was routinely deviating from regulations. The failure to comply with the technical log system regulations was specifically highlighted.

[The deviation] has instead had the stated purpose of reducing the risk that aircraft will be grounded (the operator does not have technicians stationed at all the places where the aircraft have night stops and where technical service could consequently be carried out), i.e. a purely economic purpose. This is, from a safety perspective, remarkable.

The technical log system, the failure to protect the data on the CVR and the inability to convert data from the FDR had all been highlighted by the Swedish Accident Investigation Authority previously, without seemingly any action by the operator or Lennuamet, whose responsibility it was to regulate the operator.

Further non-compliance was the decision to take off from Stockholm into severe icing conditions with the right-of side propeller de-icing system unserviceable.

For an aircraft in winter conditions, the ability to understand the landing characteristics of a contaminated runway is critical. The complete lack of performance data for the aircraft meant that the flight crew had no means of working with the friction coefficients given to them, and in fact believed that the information did not apply to them.

And finally, the fact that the first officer was unaware of the requirement for a stabilised approach and that the captain believed the too-fast approach with last minute pitch change bringing the aircraft from too low to too high could be considered a stabilised approach speaks to a clear training issue at the company.

These deviations all show systemic safety and training issues at the airline. More importantly, it is the regulator, in this case the Estonian Civil Aviation Authority, who was allowing the airline to continue to operate despite its continued disregard of regulations.

The final report ends with a single safety recommendation.

Considering the fact that the Swedish Transport Administration has terminated the contract with the operator in question, SHK has limited the report’s recommendations to only cover the Estonian civil aviation regulator, Lennuamet, which is recommended to:

* Tighten its supervision of the operator, AS Avies, in order to ensure that operations are conducted in accordance with applicable flight safety requirements, in particular with respect to such deficiencies as identified in section 2.5 of this report.

Although Lennuamet initially expressed confidence that AS Avies was responding to the safety concerns and complying with regulation, on the 1st of April in 2016, Lennuamet suspended the air operator’s certificate of the airline for not meeting the requirements laid down in regulation. The suspension was set for six months or until the airline restructures to improve its activities and addresses the identified shortcomings.

The story does have a happy ending. As far as I can see, the airline has not resumed operations.

Another well researched article. Fortunately without injuries or loss of life.

What can be said as comment:

From the summary, we can draw the conclusion that the remarks about de-icing systems, icing conditions and fuel status were not pointing at the cause of the incident. In fact, they were not related. But they do draw a disturbing picture of the unprofessional way this airline operated.

The crew also come across as lackadaisical, unprofessional, perhaps lacking in their level of experience.

Sum-total: a sloppy operation where known defects were not entered in the technical log “to prevent grounding the aircraft”. However unprofessional to accept the aircraft with one prop de-ice not functioning, it does not appear to have had a bearing on the incident either.

30 minutes between de-icing and take-off. Depending on type of fluid used, concentration and other factors a “hold-over” time will be extracted beginning from the start of de-icing and within which time the aircraft must either be airborne, or be de-iced all over again. Again, nothing happened but it seems that a long time passed between de-icing and taking off.

If the aircraft had picked up some ice when it was in the approach, yes the increase in Vref was correctly applied. A wing is a carefully designed and critical part of an aircraft. Ice will change the shape and cause drag, resulting in a higher stall speed. But this has NOTHING whatsoever TO DO with a CONTAMINATED RUNWAY.

Some pilots think that they should “drag it in”, coming in a bit low, if the runway is contaminated. Wrong, the approach should be made as normal: a 3 degree glide path as determined by ILS or PAPI.

Stabilised: another rather over-used concept. It simply means that the aircraft must be in a stable configuration with the proper speed, power setting and glide path so that the aircraft will be at Vref 50 feet above the threshold. When on a low-vis approach (Cat 2 or cat 3) the aircraft must be stable and on speed as soon as it is established on the glide slope. The P/F came in a bit low, landed long and as a result the crew failed to control the aircraft during roll-out.

I doubt that this airline will ever get its AOC back, unless perhaps the licence is taken over by a new entity who can demonstrate that the operation will be extensively revised, proper procedures and proper crew training implemented.

I agree that the crews actions (or inactions) in response to the conditions had nothing to do with the contaminated runway. However, it showed that the crew were unaware of the limitations of the aircraft and flying in severe icing conditions as well as clear non-compliance issues regarding the faulty equipment and the lack of a mention in a tech log. This combined with the complete disregard of the contaminated runway means to me that this wasn’t just a mistake or a case of get-home-itis so much as a shocking lack of knowledge about winter flying. The fact that the captain was adamant that there had been no deviation from routine or regulation and the first officer felt nothing out of the ordinary had happened points shows a real issue with the operator and with crew training. The operator of course confirmed this with the unbelievable explanation as to why they don’t log faults in the tech log.

I think the stabilised approach really *is* important though. The fact that the operator had no criteria for deciding whether the approach is stabilised or not is part of the same overall problem. In this specific flight, the Pilot Flying made a last minute configuration change because the aircraft was not stabilised, even though the Pilot Monitoring called out that it was. So there was never a thought of going around or breaking off. That last minute pitch up led to an over correction which directly led to them losing 400 metres of a 1,200 metre runway, when they required a minimum of 1,100 metres to land in. Even ignoring the contaminated runway, throwing away a third of the runway like that makes no sense at a small airfield (ok, at Luton in my Piper it never mattered much ;). But also the idea that an approach should be set up correctly seems to me to be critical in looking at safe operations.

About “friction coefficient”.

As a separate topic: When the runway is “contaminated”, i.e. presence of water, slush, snow, etc., the airport authorities will send out a vehicle to establish the braking coefficient. The method usually – unless changed in the intervening years – is a vehicle, as a rule a 4×4, with the equipment firmly attached externally. It has to be because the visual part consists of what looks like a fifth wheel on the wagon, often painted yellow. Anyway, retarding force (braking in other words) is applied to this wheel. Depending on the nature of the contamination, eventually this wheel will lose it’s grip on the runway surface and will start to decelerate. In other words: it will start to drag rather than rotate. The vehicle itself will, of course, not brake. The braking force applied to slow down rotation is relative to the adhesion of the measuring unit’s wheel and can be translated into “friction coefficient”.

This in turn is transmitted to the crew as “braking action”: good, medium or poor. Needless to say, if the vehicle itself skids off the runway, the braking action can be regarded as “poor” (or non-existent) and the runway will have to be closed, to retrieve the vehicle and to remove the contamination if possible.

The crew will have information in the ship’s library telling them what extra margin to apply to the required runway length and compare it with the available length of the runway itself.

In the incident described here it would appear that the available runway had been adequate. It was just a matter of poor airmanship.

Pilots of smaller aircraft, and here lies the rub, are getting used to runways that more often than not are laid out to accommodate larger jets. They simply are getting dumb, fat and happy operating in and out of airports that have runways often twice the length required for their type of aircraft.

The crew of the larger jets on the other hand are faced with critical runways all the time and often are much more alert to assessing whether or not they will be able to land safely in the event of contamination.

Thanks for the additional info on this. I have no practical experience of how this works, so it’s interesting to get the detail.

I guess you could say they had…

*…Stockholm Syndrome!”

Ok! Ok! I’ll leave…

*groan* That was terrible!

You may have a point, Andrew ;-)

Even though the crew made quite a few bad decisions and ignored safe practice about winter operations, in the final analysis none were a factor in this incident. Even the fuel was adequate. There is no mention of the aircraft having accumulated more ice than the aircraft was able to cope with, perhaps it did not even have any ice accretion at all. The crew seemingly never even checked. The contaminated runway had an effect in that apparently the crew failed to treat the runway, under the circumstances, as ‘critical’ and the captain failed to take action when the approach technique of the handling pilot was putting the aircraft in jeopardy.

What exactly happened, the sequence of events, cannot be established because the crew even blissfully broke the law by allowing the CVR to keep running whilst they were on the mobile phone talking to their operations department.

Not an operation that instills confidence; unprofessional is a kind way to describe it.

Sylvia, you are quite right. The aircraft was not stabilized in the approach and in my opinion, having nothing else to base this on of course, this would have been the main cause of the incident.

Avies AS plans to resume operations within one or two months, this time corporate and charter flights.

http://news.err.ee/v/business/fcd6d645-6c81-4785-b2c6-2f6290495ddf/estonian-carrier-avies-to-resume-operation

http://news.err.ee/120558/estonian-carrier-avies-to-resume-operation

They have also regained their AOC.

http://news.err.ee/v/business/25b08ea8-b87c-42f4-a065-1637cd6a9db9/avies-recovers-certificate-prepares-to-resume-operations

http://news.err.ee/118893/avies-recovers-certificate-prepares-to-resume-operations

news.err.ee is an estonian news agency.

The more, the merrier… ;-)

cheers/Rolf

Wow, thank you; I’d missed that completely! Well, I sure do hope that they have tightened up their operation and understand the point of the technical log book, now.

Don’t we all… :-)

There’s much more to their sloppy operations in Sweden than may be apparent from that Torsby incident. Like aircraft being mended with tape, broken or corroded pipes, City Hall recommending their employees to avoid flying Avies, regional police authorities forbidding their employees to book Avies flights, Avies not flying for a week to certain destinations, punishment fees for cancelled flights, a passenger valise drenched by aircraft fuel during flight; hydraulic system accidentally shut down during flight, then restarted during flight, whereupon hydraul oil started leaking, crew had to crank out landing gear by hand; Avies indebted to the airports, risking bankruptcy, having to pay for fuelling before take-off, Avies being unable to pay debts down to a few hundred dollars, angry editorials (heavy on the vitriol), and more…

Avies was the mother company Avies AS in Estonia, and a swedish daughter company Avies Sverige AB. The swedish company was the one actually flying in and to Sweden. The swedish company is bankrupted, finally, and the mother company is still technically alive.

If you’re interested I could send you privately a file I have compiled about the entire sordid story. Most of it is in swedish though, so you may have to pour it through Google Translate. It’s about 315 KB. Pure .txt file collected from october 2014 up until today.

cheers/Rolf

It’s quite clear from the Torsby report that the Swedish investigators were deeply unhappy with Avies from past incidents although I haven’t delved too deeply into the detail. If you would like to send your notes to me ([email protected]) then I’d love to have a look, although I’m not sure how much sense I’ll be able to make of it.