Aeroperú Flight 603

On Tuesday, the 1st of October 1996, Aeroperú flight 603 departed Miami for a scheduled passenger flight to Santiago, Chile, and landed in Lima, Peru for a planned stop to refuel. The aircraft was a Boeing 757-200 with two flight crew and seven cabin crew. In the cabin were sixty-one passengers, mostly Chilean but also twenty British travellers and a scattering of other nationalities, who all wished to go to Santiago.

The flight crew had reported a bird strike when they landed at Jorge Chavez International airport, Peru’s main international and domestic airport. They had ingested a bird into the right engine. While on the ground, the right engine turbine blades were changed and the front of the fuselage was cleaned.

In order to clean the right side of the fuselage, it was necessary to protect the pitot and the static ports from contamination. The pitot measures the dynamic air pressure and the static ports measure the static air pressure: between them, they provide the altitude and the airspeed to the flight crew.

A line mechanic covered the static ports on both side of the aircraft with masking tape to protect them. He then cleaned and polished the fuselage, as per his instructions. He should have removed the tape when he finished but somehow, he forgot to do so and didn’t check his work. Worse, the quality control staff member who supervised the finishing of the job didn’t notice that the static ports were still covered with tape. The duty supervisor handed the aircraft to the flight crew without checking that the job had been completed correctly.

The final chance to spot the problem was the pre-flight checks, which specifically included a visual check that the static ports were clear. However, when the captain did his walk-around, he clearly didn’t spot the tape, a dull silver colour, covering the static ports high off the ground.

The flight departed Lima just past midnight, local time, with the first officer as the Pilot Flying and the captain in the role of Pilot Monitoring, although they wouldn’t have referred to their responsibilities as such at the time. As the Boeing 757 climbed away from the runway, the first officer asked for the landing gears to be retracted. Instinctively checking their height at this point, he realised that there was something wrong. The altimeters were stuck.

As he called out, he was interrupted by the wind shear alarm, which sounded three times. The captain told the first officer to keep the airspeed up and asked if he was descending, at the same time, the first officer said that he was climbing.

The captain attempted to call the Tower but he was interrupted by the rudder ratio alarm, which serves as a warning to the pilots not to use large or abrupt rudder inputs.

The flight displays told them that their airspeed was too low and that they were not climbing. They had no frame of reference looking out at the dark night. The air traffic control staff in the tower saw the aircraft level out briefly and then climb away, disappearing into the clouds.

The displays and the alarms in the cockpit made no sense and the flight crew could not work out what they needed to do. The captain was primarily concerned about the altitude and that, as far as he could see, they weren’t climbing properly. The first officer was worried about the low indicated airspeed and thus did not want to increase his rate of climb for fear of stalling the aircraft.

As the captain attempted to find out why the rudder ratio alarm was sounding, the first officer checked the source selector, clearly suspecting a blocked static port. The source selector collects the air data from a different static port. However, it made no difference as all of the static ports had been taped up. The back-ups exhibited the same failure as the primary systems.

The Mach trim warning sounded while the rudder ratio alarm was still blaring. The captain called for basic instruments, attempting to limit their information to the most trustworthy data. The first officer called ATC to declare an emergency. At this stage, they were flying through a low layer of cloud at night with no visual references and they were unsure of their height, their speed, the state of their rudder and the state of their stabiliser.

Jorge Chavez International Airport had a radar surveillance system which was being tested, so the controller asked the flight crew to switch frequencies so that ATC could offer them radar advice and support.

The captain took control of the Boeing 757 while the first officer spoke to the controller to coordinate a return to the airport using the Instrument Landing System (ILS). Meanwhile, they both tried to resolve the alarms in the cockpit and get a handle on what, exactly, was wrong.

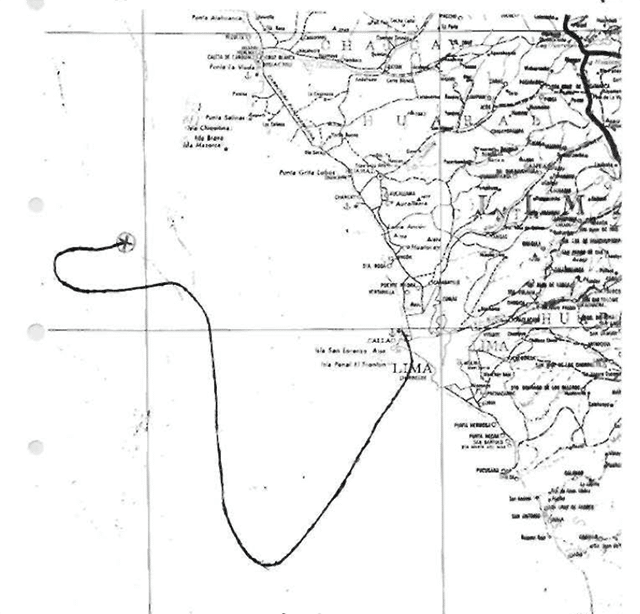

They flew out to sea so that they did not have to worry about terrain: the foothills of the Andes are just north of Lima. Here was the safest space for them to troubleshoot the problem and safely return to the airport.

The first officer asked the air traffic controller for confirmation of their flight level and the controller responded with 4,000 feet.

This must have been a great relief to the flight crew, as it corresponded to what the altimeter was showing. They focused again on the rudder ratio and their airspeed, which still appeared to be low.

But the controller was using secondary radar, which means that he was picking up the altitude information from the aircraft’s transponder. He’s not confirmed their height. All he has done is repeat the same wrong information that their altimeter was showing them in the cockpit. The partially blocked static ports are not able to measure the air pressure correctly and the height information is not to be trusted. Worse, the crew now believe they have independent verification that their altitude, at least, is correct, so now they can focus on solving the problem.

As the Boeing 757 continued to climb, the first officer asked the controller to confirm their airspeed and altitude. Those are the two parameters needed for safe instrument flight. The controller responded that they were currently climbing through 6,000 feet. The first officer said that their altimeter showed 7,000 feet and the controller confirmed that was correct: Now reading seven zero.

It didn’t occur to anyone that they were reading the same faulty data back to each other.

The first officer told the controller that they had control problems. The aircraft should have been handling fine, so he probably meant the rudder ratio and mach trim alarms. In the cockpit, the flight crew worked through what seemed most likely to be the relevant checklists while climbing to 12,000 feet out to sea. The first officer checked the alternate air source again, clearly suspicious of the air data. But again, as all of the static ports were blocked, it did not help.

Earlier that same year, another Boeing 757 suffered these same inexplicable warnings. The NTSB investigation concluded that the pitot-static system had failed because of a wasp’s nest built in the pitot tube, obstructing it. They recommended that the 757 flight manual include the information that if the rudder ratio and the mach trim alarms go off at the same time, it’s a symptom of an airspeed discrepancy and likely a failure of the air data. However, as it had only happened once, this information was not disseminated as a matter of urgency. The Aeroperú flight crew had no idea.

All they could do was to attempt to solve the problem, if possible, and then return to the airport and intercept the localiser on the ILS, the Instrument Landing System.

The Instrument Landing System is based on airport runway information being transmitted from the ground and received in the cockpit, so the data is not affected by the faulty systems on the aircraft. It consists of a localiser and a glide slope. If they could just get onto the localiser, they could simply follow the glide slope to bring them down.

The flight crew asked again for assistance with altitudes and speed until they could be guided to the localiser. It was clear to them that their instruments couldn’t be trusted.

Air Traffic Control gave them a new heading to turn back and followed this with full instructions, in case they lost radio communications. They needed to turn right to intercept the localiser to complete the ILS with a descent of up to 4,000 feet.

The flight crew followed the vectors from ATC and attempted to set up for a landing in the dark with no auto-pilot, no Flight Director and no auto-throttle. As they entered the descent, the displayed airspeed started to increase rapidly. The overspeed warning sounded, another alert which needs immediate and attention and action. If the aircraft were overspeeding, the engines could flame out or even be destroyed, taking Aeroperú 603s situation from bad to catastrophic.

The flight crew reduced the engine throttle immediately. The rudder ratio alarm sounded again. Both pilots agreed that the instruments and at least some of the warnings had to be wrong but what was their actual status? They had no idea.

ATC confirmed that they were 31 miles west of the airport at just over 10,000 feet with a speed of 270 knots over the ground. This was the first time that ATC had given them their groundspeed. The cockpit display showed an airspeed of 350 knots.

The airspeed was wrong. So was their altitude. But as they continued their descent, the overspeed alarm sounded again and continued to sound, even after they reduced the thrust and activated the air brakes.

The stick shaker activated again, vibrating the control columns. This indicates a high angle of attack, which means that the aircraft is in danger of stalling. According to the multiple alarms going off in the cockpit, the Boeing 757 was both flying precariously slowly and hazardously quickly. Both situations are urgent an both require immediate action but which one? The wrong decision would make things worse.

The first officer asked ATC for another aircraft to join them. Someone in the air could confirm their altitude and determine their true airspeed, which was either dangerously high or dangerously low. Another aircraft might also have spotted that the Boeing 757 was in a gentle descent. The flight crew had no idea: the altimeter was not changing and the controller was mirroring the false information.

The stick shakers shook the columns and the alarms continued to sound. It must have been a nightmare trying to think straight. The first officer believed that they were stalling. The captain believed the overspeed warning. Both of them believed that they were at 9,500 feet.

Then the Ground Proximity Warning System kicked off with TOO LOW, TERRAIN, calling into question the one fact that they thought they knew. It sounded twenty-two times over 45 seconds. The captain panicked, thinking they must have flown over the coast and are heading into the mountains, the only sensible reason why their height over the ground could have changed so quickly. The first officer reported the warning to ATC, who confirmed that no, the Boeing 757 is definitely out to sea, flying northwest at FL100, 10,000 feet above sea level.

The Ground Proximity Warning System uses the radio altimeter, not the barometric altimeter. Here, finally, is information that they could trust. The barometric altimeter uses the faulty air data but the radio altimeter is independent, bouncing radio waves up to reflect off the ground. It is only useful at range but it gives the true distance between the aircraft antenna and the ground directly below it. The Ground Proximity Warning System was configured to sound if the radio altimeter showed that the ground was less than 2,500 feet away while the aircraft was not configured for landing.

This means that the flight crew have two pieces of data t hat they can rely on: their true height above the ground from the radio altimeter and their ground speed from the radar readings. At low level, knowing the wind direction from their take off only a few minutes before, they could calculate their approximate airspeed, at least close enough to know whether they were overspeeding or at risk of stalling.

However, they had been so bombarded with information that the cockpit resource management has fallen apart. They no longer are working as a team and they became unable to agree on any clear decision as to what their situation was or what they needed to do.

The aircraft entered a gentle climb, too subtle to notice in the dark over the water. As they ascended over 2,500 feet, t he terrain waning stopped. As they still believed that they were flying straight and level, this must have seemed like confirmation t hat the alarm was wrong. “It must be fictitious,” said the captain, dismissing the Ground Proximity Warning System as one of the clearly false alerts in the cockpit.

The aircraft then descended 700 feet and a SINK RATE alert sounded. The truth was that they were stalling and dangerously close to the dark sea. The aircraft’s height above the sea shifted repeatedly over this time: they climbed to over 2,400 feet and then descended sharply enough to set off a sink warning before climbing to 4,000 feet where they levelled out again. Throughout this, the altimeter showed only minor changes and that they were consistently above 9,000 feet. The controller confirmed it.

He asked a Boeing 707 to depart the airport and help guide the 757 in. The Boeing would make visual contact with the Aeroperú aircraft, allowing them to understand just what was going on.

The flight crew turned and entered their descent to 4,000 feet, ready to intercept the localiser for the Instrument Landing System. They reduced their their thrust to idle and yet the overspeed warning continued to sound. The Ground Proximity Warning System sounded again and kept sounding: TOO LOW, TERRAIN. TOO LOW, TERRAIN. The first officer checked their altitude and queried ATC again. Both the instruments and the radar showed that they were at 9,700 feet. They continued their descent.

The aircraft touched the water as the the first officer called the controller, who for the first time noticed the terrain warnings in the background. The captain shouted PULL UP, PULL UP as the controller called out the same, GO UP! GO UP IF IT INDICATES PULL UP! He knew that the Ground Proximity Warning System should be trusted over the radar information that he was passing on.

The captain pulled up and the terrain warnings briefly stopped. But the Boeing 757’s speed was already precariously low and now it decayed to the point of a stall. The Captain realised he’d lost control of the aircraft; as the aircraft banked left, his last words were, “We are going to invert.” There was no chance of recovery.

As the Boeing 757 crashed into the sea, the captain’s airspeed showed on the display as 450 knots and the altimeter still read 9,700 feet above sea level.

Only at the very end would the passengers have been aware, as the previous climbs and descent were too gentle to be felt. They, like the flight crew, could see nothing out of the windows other than the black night and the lights of the wings reflecting off the low cloud.

The left wing had been badly damaged when it clipped the water and although the captain managed to get the aircraft airborne again, the aircraft inverted and impacted the water. There were no survivors. Only nine bodies were recovered.

Divers confirmed that all three static ports on the left side were covered with masking tape. They could not reach the right side but it seems reasonable to assume that the tape placed there had not been removed.

This was the third Boeing 757 crash in ten months. In the aftermath of the crash, Aeroperú filed for bankruptcy. Boeing paid compensation to the families of the victims, taking responsibility for failing to train pilots to deal with this circumstance but not for the disaster itself. The cause of the cash, the static ports being covered, was, they said, caused by careless maintenance and a negligent pre-flight inspection by the captain.

The NTSB recommended that conspicuous covers be used to cover static ports during aircraft cleaning operations in order to ensure that they were visible. These covers now also have warning flags in order to make it even more obvious if they are covered.

The line mechanic was convicted of negligent homicide.

“The stick shaker activated again, vibrating the control columns. This indicates a low angle of attack…”

The stick shaker indicates a high angle of attack.

Argh. Fixed.

Ed is right. I don’t know the 757 but at a guess the stall alert system* also would need input from other sources, not just from the angle of attack vanes alone. In the latter case, ironically it would have been a reliable indicator of an airspeed that was too low.

This guess may be wrong of course. I have once suffered an in-flight loss of airspeed indication. The pitot heat could not adequately cope with certain conditions and they just froze up in cloud. The IAS on both sides started to drop, eventually to way below stall speed.

I had to rely on the angle of attack indicators to ensure that at least we were still flying at a safe speed. Eventually we got out of the clouds and all returned to normal. We were not far from St. Nazaire where the aircraft had been built and we diverted there to have it checked. A modification of the pitot tubes was ready to be installed which caused raised eyebrows: had Aerospatiale known about this problem and withheld the information?

The Aero Peru crew were not so lucky. They were overwhelmed with a high number of alerts and warnings that the crew were presented with. It would have overloaded many if not most pilots.

*Stall alert system: with that I mean stick shaker and -pusher.

Covered/plugged pitot-static systems have killed a lot of airplanes and people.

The only B-2 bomber loss was semi-clogged pitot-static ports. At $1.4B it’s supposed to be the most expensive crash in history.

Wikipedia says:

Whelp. Nothin’ like leavin’ it to the absolute very last second!

Negligent homicide sounds appropriate, but for more people, not just the line mechanic. Negligent justice as well here.

There’s a widespread tendency to dump on people directly doing work and not on supervisors who are supposed to make the work happen properly; I’m not surprised that happened here.

I agree: it is much too easy to knock out the lowest person in the chain of command and step back, happy that the problem is solved.

This is unusual; normally bringing down a passenger plane takes a whole string of things going wrong. I wonder about overall procedures: should masking tape have been part of the maintenance kit at all? Is there anything else it could reasonably be used for? ISTM masking tape is an especially bad choice; they could have used gaffer tape, which leaves no residue, comes off whole (masking tape tends to shred) and is available in bright colors. Maybe even something packaged in single pieces like surgical sponges, so there’d be an indicator in the kit that cleanup as necessary (as I understand surgical crews count the sponges retrieved against the number of packages opened, to make sure none are left inside the patient). This all happened 25 years ago; have procedures been tightened since?

I believe that it was standard practice at the time to use brightly coloured tape but it wasn’t mandated. For some reason, the line mechanic that day didn’t, which made it very easy to miss. After this, of course, the risks were clear and the requirements were changed.

Here’s a 3-year-old article covering the same accident: https://fearoflanding.com/accidents/accident-reports/it-must-be-fictitious-aeroperu-603/

I wonder what prompted this more concise rewrite?

Well spotted! I thought about mentioning that but then ran out of time. After writing the first piece, I was invited to talk on Air Crash Confidential about the crash. They sent me a list of questions and I noticed that my existing piece didn’t actually address many of the things they wanted to know. I ended up researching the whole thing from scratch to make sure it was clear in my mind and then realised I had done 70% of the work towards a Fear of Landing post. I went back and forth about whether to use it and then decided it was different enough (and most people’s memories are short enough :D) to be worth finishing, on the basis that the two articles together gave a more complete view of the accident.

I don’t think I’ve ever done that before although I used to repost articles that were a few years old if I felt they would be new to the current audience. Adding the “Related Posts” function to the website meant that got really weird quickly, though, so now I just leave them in the archives.

Thank you!

It’s always interesting to learn what goes into your research!

It can be very dangerous to cover something important with material of a colour that matches the surrounding area of the airframe.

How many pilots made mistakes, overlooking something in the walk-around, used the wrong procedure in the emergency checklist, misread the weather briefing or something else that thanks to a bit of luck they got away with? Or if not, did not lead to headlines in the press

I heard of a pilot who forgot to remove the engine covers from his engines of. He had made a relatively short stop, a few hours, and normally he would have parked the aircraft without the blanks in place. But it was in the Middle East, there was a strong wind and that caused a sand storm. So he covered the engine intakes. And of course forgot to remove them when starting up. A jet engine does not take kindly to bits of chewed-up canvas sucked into the fan, the compressor and probably also the hot section. It was told by a type rating instructor, it was meant as a warning. We were not told the aftermath.

I confess, something equally stupid has happened to me too.

It must have been in 1969. My first job as a commercial pilot was towing advertising banners. Our base was Essen-Muelheim (EDLE) in Germany. Banner towing was big business then. There were usually 17 to 21 Piper Super Cubs flying, every day of the week except Sundays because of the local law. Every day, nearly literally so because we got paid by the hour. We averaged 40 hours per week, often more because on Sundays we often were recruited for sightseeing flights in Cessna 172s, or photo flights. Even asthma patients who got relief from a flight at 10.000 feet.

We were assigned a PA-18 for the banner towing, and normally we kept that aircraft to the extent that we were very much tuned in with “our” Super Cub. We even felt strange in another Piper if our usual one was in for maintenance. There were a few that were considered to be the best performing ones, like D-EGGA and D-ELIH.

But I digress.

The flaps of the Super Cub were held in the “up” position with a spring. The selection of flaps, was by a handle on the left side of the pilot’s seat. This pulled the flaps down, against the spring.

If the spring broke the flap would dangle down loosely. It did not affect the operation of the aircraft. In flight, the aerodynamics would keep them in place and selection of flaps was still as normal.

Still with me? I confess, this is a rather elaborate way of leading to my mistake.

When parked, a strong wind from behind could force the flaps – well, to flap in the wind. The gust lock did not incorporate the flaps.

Overnight, he Pipers were anchored to fixed tie-downs. Very secure but we always parked in the same position. So if a strong wind was expected, we would park with the flaps down.

The company decided that in a strong wind from behind, this could put a lot of strain on the flaps, so they devised an alternative. Of which we were not told.

One day the weather had been really bad in the morning, so we were playing cards in the crew room when suddenly it was decided that we were to get ready at once.

A few days previously we had been lectured by the Chief Pilot. Some of us had taken too much time for the pre-flight. We all flew the same aircraft every day. In order to get 20 or so aircraft in the air, all at the same time and get them to pick up the correct banner required a bit of choreography; we were told not to “waste” time with an overly elaborate pre-flight.

I ran to “my” Piper which had been parked where I had left it. I had flown this same aircraft for the past weeks, 8 to 9 hours a day. Before I had parked it, I had refueled it myself. With the words of Herr Pfannkuch fresh in my mind, I quickly checked the oil, did the fuel drain and off I went.

Because of the strong, gusty wind I took off without using flaps. Usually the pick-up run was done with one notch of flap but again, there was a stiff breeze so I did my run with them retracted.

Up to then, all was normal. I seemed to have full and normal control.

But after I had the banner safely hanging behind me and waiting for the rest of my formation (we operated a formation of 3 aircraft) I selected one notch of flap.

Instantly, the aircraft banked left. I could not stop the roll until I retracted the flaps again. Eventually I discovered the cause: because of the forecast of high winds overnight, the mechanics had manufactured wedges made from scrap aluminium and had them inserted over the ailerons and the flaps. The idea was to connect the flaps with the ailerons so that the flaps would be immobilised by the gust lock. The problem was: they had done this quickly the previous evening. The wedges were white. So were the flaps and the ailerons. They went unnoticed by me.

When I taxied to the runway, still with high wind, I did test the ailerons but not to their full extent. One wedge must have dislodged itself before take-off. But the other one stayed in place. When applying aileron, it pulled the flap down with it. I had no problem with the control over the aircraft. But when I extended the flaps, the starboard one pulled the aileron down with it so the aircraft entered, as experts would describe it, “an uncommanded left turn”.

Once I discovered this, I managed to dislodge the other wedge by wriggling the controls, and continued the mission.

So what is the moral of this long-winded story?

I was the one and only person to be blamed. I had done a sloppy pre-flight check and had not even done a proper check of the flight controls. Yes, the wedges should have been in a contrasting colour, they were the exact same colour as the flaps and ailerons.

But ultimately I was responsible.

Fortunately, it did not even lead to a written report. Only to an embarrassment with the benefit of a valuable lesson learned.

It is your responsibility as the pilot, of course, but this is also a clear demonstration of how the pilot is often the last safety net and thus ends up carrying the blame for any other mistakes or bad decisions higher up the chain.

In the US the response would have been to name these wedges Pfannkuchen — or to find something ruder to hang his name on. A hurry-up direction from management is an invitation to disaster.

Chip, that is funny. The name Pfannkuch was the actual real name of the chief pilot of the banner towing operation at the time – `1969.

Sylvia, I agree with you but in cases of not properly checking items, be they part of a walk-around, a flight briefing or anything that is officially the remit of the pilot, the latter ALWAYS will end up being responsible.

I gave one example but there are more:

Doing the preflight of the Cessna 310 for a flight from Amsterdam to London Gatwick I noticed that the oil level of the starboard engine was a bit low. My boss was the only other occupant. He was fully rated on the aircraft but did not always flew it himself. He had arrived, I asked the mechanics to top up the oil which they did.

The dipstick was at the rear end of the engine, the filler at the front under the cowling, just behind the propeller. The cover was properly closed. We departed.

Halfway across the North Sea my boss tapped me on the shoulder and pointed to the engine.

Oil was coming out from under the cover and soon formed a river that covered the right engine with black ripples.

“Shouldn’t we return to Amsterdam?” my boss asked.

I suggested that as we were halfway over open sea we might as well continue, at least he could keep his appointments. We kept a close eye on the engine gauges, but the oil temperature and -pressures remained normal, no need to declare an emergency.

At Gatwick I got a lot of rags and cleaned the engine.

The filler cap had not been replaced properly and anyway was held attached to the engine by a chain.

After a while I checked the oil level.

We had not lost much oil at all, I did not even have to top up.

But if this had led to an incident, it was made clear that checking that oil filler caps are properly closed was my responsibility.