Boeing 737-900 MAX loses its cool

Well, 2024 sure has arrived with a bang. It’s a little too soon to draw firm conclusions about the MAX 9 incident, but let’s see what we’ve got so far.

On the 5th of January, a Boeing 737-900 MAX registered in the US as N704AL was operating Alaska Airlines flight 1282, a scheduled passenger flight from Portland, Oregon in the US to Ontario International Airport in California. There were 171 on board.

Shortly after departure, after climbing through 14,000 feet, the cabin experienced a rapid decompression. Flightradar24 shows the maximum altitude as 16,325 feet above mean sea level.

The flight crew quickly reacted, entering a descent and declaring an emergency. The flight returned to Portland safely. The aircraft was airborne for 20 minutes.

You can hear the ATC audio on this video by REAL ATC on YouTube:

The Boeing was just a few months old, with its first flight on the 15th October 2023 and delivery to Alaskan Airlines on the 31st.

It had operated 134 cycles (a cycle is a single take-off and landing) by the end of the year, thus there should not yet be any risk of fatigue.

Passengers heard a loud bang as a door-sized hole suddenly appeared in the middle of the cabin. The oxygen masks dropped.

This video from TikTok was taken by a passenger seated a few rows back:

@strawberr.vy Girls’ trip turned into emergency landing trip… alaska alaskaair ♬ original sound – vy 🍓

The cabin crew, still in their jumpseats, were very unsure as to what was happening as they had difficulty seeing into the cabin. At the same time, the flight crew were taken by surprise by the cockpit door opening. This apparently automatically happens on a rapid decompression; however, this was not documented in the flight crew procedures.

Thankfully, the two passenger seats next to the breach were not occupied. Passengers were still seated with seatbelts on and the fuselage part — now known to be a door plug — did not strike any other part of the aircraft as it detached.

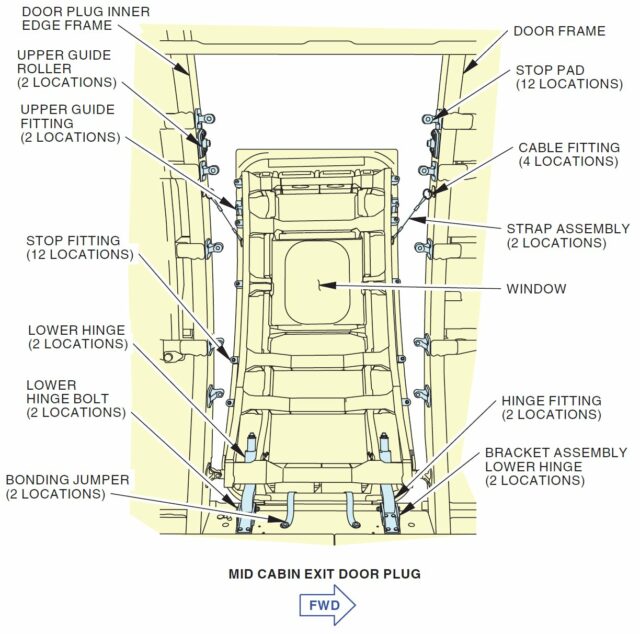

The 63-pound door plug (28.5 kilos) was in place to seal an unused emergency exit. The mid-cabin exits in the 737-900 are optional and for most operators, they are deactivated. If deactivated, the exit is blocked with a door plug, a door-sized piece of fuselage with a window. Inside the cabin is a standard interior sidewall.

The NTSB made press statements every day from Portland for the first three days after the incident.

On the first briefing, they asked for help in retrieving the door plug.

School teacher Bob Sauer saw the news but didn’t realise that he was in the drop zone until late on Sunday evening. OregonLive reported on the find:

It was dark and raining out. As he stepped around the corner of his house, he shined his light along a bank of cedar trees that he and his children had planted about 20 years ago to separate his property from his neighbor.

Suddenly, he noticed something white gleaming in the beam of his flashlight. He stepped a little closer, and there was the “missing piece from the airplane,” he said.

Sauer was interviewed during the beginning of his Monday morning astronomy class. Reporters were treated to an unexpected physics discussion as he explained how the door plug slowed down as it fell through the trees.

NYT: Science Teacher Finds Missing Piece of Boeing Jet’s Fuselage in His Yard (paywalled)

He said that the 50-foot cedar trees in his yard had acted on the same scientific principle as an airbag, disrupting the door plug’s fall — in an act known in physics as impulse.

“Impulse is what you do to change the momentum of something,” Mr. Sauer said. “You can do it with a big force over a short time, or a smaller force over a longer time.”

He said an even more relevant lesson, beyond the sheer physics of the drop, was that amazing things can happen.

Meanwhile, Boeing’s CEO released a statement saying that Boeing must acknowledge their mistake and did not argue the grounding of MAX 9 aircraft in the US. The Guardian published details of the internal meeting at Boeing.

“We’re going to approach this – number one – acknowledging our mistake,” Dave Calhoun told Boeing employees at an all-hands meeting at its factory in Renton, Washington, where 737s are assembled, on Tuesday. “We’re going to approach it with 100% and complete transparency every step of the way.”

The US government’s Federal Aviation Administration (FAA) stated that they were conducting a separate investigation, saying, “This incident should have never happened and it cannot happen again.” They published the letter notifying Boeing of the investigation on Wednesday.

ALLEGED NONCOMPLIANCE:

The above-described circumstances indicate that Boeing may have failed to ensure its completed products conformed to its approved design and were in a condition for safe operation in accordance with quality system inspection and test procedures.

This is a striking contrast to the Boeing and FAA response after the first crash of the MAX 8, Lion Air flight 610.

Jon Ostrower and Will Guisbond, writing for The Air Current, heard from unnamed insiders that the aircraft in question had pressurisation alerts the day before.

The first intermittent warning light appeared during taxi-in following a previous flight, which prompted the airline to remove the aircraft from extended range operations (ETOPS)per maintenance rules. The light appeared again later the same day in flight, the people said.

If you’ll allow me a bit of gallows humour in an incident with a happy ending for everyone but the aircraft and no injuries, I was sent this image which made me laugh out loud.

The focus at the moment seems to be on four stop bolts which prevent the door plug from moving upwards and disengaging the 12 stop pads. All 12 stops were disengaged; however, the four bolts have not been recovered. The NTSB stated in the Tuesday briefing: “We have not yet determined if they existed.”

Meanwhile, in the United States, all 171 Boeing MAX 9 aircraft (operated by Alaska Airlines and United Airlines) are grounded until they can be inspected, a process which takes about 8 hours per aircraft. There are another forty-four MAX 9 jets in service outside of the US. Airlines in Brazil, Mexico, Indonesia and Panama have suspended operations of the affected MAX 9 aircraft pending an inspection. Chinese airlines have not accepted any Boeing MAX aircraft since they initially grounded the model in 2019.

There are no known MAX 9 aircraft with door plugs for the mid-cabin exit operating in Europe or the UK, so please, don’t panic if you realise that you are flying in the window seat of a 737-9 this weekend.

Please feel free to add further information and links in the comments (but keep it to one or two links per comment, else you’ll get thrown into moderation).

Hi, I believe it is Ontario California not Ontario Canada. I agree that when they write Ontario CA it can easily be mistaken for Canada. Thanks for your detailed article Sylvia!.

Argh. Fixed! See below.

As a side note – I live in a city in Ontario, Canada, and many years ago I was flying out of IAH when my flight changed gate… and a plane flying to Ontario, CA, USA ended up at the gate I was originally departing from.

Sure enough my luggage got a nice round trip to California before finally following me home. I’ve always wondered if the breakdown was related to the name.

“…from Portland, Oregon in the US to Ontario International Airport in Canada.”

CA, but California, not Canada. https://en.wikipedia.org/wiki/Ontario_International_Airport

Thanks both of you. I used to live near Ontario in California and quite frankly, I just assumed that Ontario International must be Canada, because the airport I knew was quite small and only used for local flights. I see it has been Ontario International Airport since 1946, so I really have no excuse.

I am really surprised by this design.

My understanding was that historically doors (main and emergency) were designed to open inwards, before pivoting and then going out. This was so that air pressure locked the doors in place and made it impossible to open them at altitude. This was in response to various early air disasters where doors (especially cargo doors) were just held in place by latches, and high altitude failures led to aircraft loss.

Looking at the picture of the lost door plug opening, and videos of “normal” emergency door operation https://youtu.be/ZFNU0cc29OQ it appears that the the 737 MAX doors are just locked in place by a roller mechanism, and open directly outwards, suggesting you could (if suicidal) open at 30k feet.

This would also make the bolts being tight and wired, absolutely safety critical…

Can anyone comment on whether there has been a change in whether doors are “pressure locked”. and if so, when and where? Was the change made to reduce exit times, and allow more people on board?

In particular I had in mind the DC10 cargo door design, which led to several catastrophic failure due to the outward opening design, and latch failures (followed by explosive depressurization, floor failure, and loss of control).

At the time I believe the outward design (as opposed to inward opening) was an outlier, and afterwards almost everyone used inward designs. I have also definitely flown on many planes when inward opening of all doors is the norm.

However, perhaps this was just a phase, and outward is again in vogue and I just didn’t notice.

There’s more detail on how it is held in place here: https://www.youtube.com/watch?v=kKSNdqtG3dY&t=0s which is by the guy who runs the http://www.b737.org.uk site. He also did this one: https://www.youtube.com/watch?v=nw4eQGAmXQ0&t=363s which talks about the doors in general, and might answer your question, but I haven’t watched it yet.

Excellent detailed videos. Confirms the doors aren’t “plug” (i.e. tapered, and bigger inside than outside), rather latched onto stop plates, and open up and out. Very hard to see how it could have opened if the 4 locking bolts (which have castle nuts and lock pins) were in place…

Remember this? I do.

Miracle Landing of Aloha Airlines Flight 243

https://m.youtube.com/watch?v=IRClHOvTSzw&pp=ygUeQm9laW5nIGZ1c2VsYWdlIGZhaWx1cmUgaGF3YWlp

Also here:

https://m.youtube.com/watch?v=QzfQXBLxSdo&pp=ygUeQm9laW5nIGZ1c2VsYWdlIGZhaWx1cmUgaGF3YWlp

And here:

https://fearoflanding.com/accidents/accident-reports/aloha-air-243-becomes-relevant-thirty-years-later/

OK, I FINALLY found a fuselage diagram showing where the plug was. All the pictures are from the interior, so I had no idea where it was on the plane.

It’s aft of the wing, and below the stabilizer. So my worry about it striking the wing/engines/stabilizer was unfounded. I originally thought it was just aft of the standard exit.

Thanks to Reuters: https://www.reuters.com/business/aerospace-defense/how-is-panel-that-blew-off-plane-made-how-did-it-break-2024-01-09/

Those intermittent warning lights interest me! I have no idea how they work but could the plug have started to move and “leaked” some of the cabin pressure? Finally giving way!

I believe I read that because of the warning lights the aircraft was not to be flown over water! Very odd!

I also wonder if the bolts were ever fitted to the door plug.

Chris

I’m in the Portland area (a few miles west of where the door landed). Local media has noted that this is the second time in under 3 months that an emergency landing at PDX has been in the international headlines.

OregonLive also has this story looking back at a 1990 incident when a passenger was partially pulled out of a plane on an Alaska/Horizon flight from Portland to Seattle after a window came loose.

Now I understand Star Trek’s impulse engines! :)

Another incident:

This is your captain screaming: Incredible story of the British Airways pilot who was sucked out of a cockpit window mid-flight 30 years ago yet lived to tell the tale – thanks to a flight attendant who held on to his trouser belt

It was June 10, 1990, and the flight crew had performed a routine take-off

But then the windscreen of the Malaga-bound plane blew out over Didcot

For the next 22 minutes the crew fought to save the captain – and the aircraft

By TED THORNHILL, MAILONLINE TRAVEL EDITOR and PRESS ASSOCIATION

https://www.dailymail.co.uk/travel/travel_news/article-8954251/A-B

https://m.youtube.com/watch?v=rGwHWNFdOvg

The investigations are still ongoing, so there is not really anything more to add.

We all agree that it was a lucky coincidence that nobody was seated beside that door plug. The crew appears to have handled the situation well, there were no injuries. Fortunately not on the ground either. That door plug could have caused a serious accident; it could have fallen on a busy highway, or struck a person.

That other parts of (new) Boeing aircraft have been found to have been improperly fitted is a source of concern.

No airlines outside the USA seem to have been fitted with door plugs, like in this incident. Ryanair chief O’Leary was quick to make that comment, and he has an outstanding order for 152 737 Max aircraft.

Even if he would consider changing to e.g. Airbus, this would not be easy. His relationship with Boeing, and the quantity of aircraft he has on order, give him a very strong bargaining hand, and a priority position on deliveries.

For a low fares airline, cost control is paramount. Switching to a new type of aircraft will involve crew- and maintenance staff to be retrained.

This was a selling point for the 737 Max: it still was a B 737, so crew only needed to complete “differences training”.

It might be argued that the Max in fact differed so much from its original 100 and 200, even the later versions, that it should have been considered to be a new type. When Fokker introduced the F50, it was designated “F27-50”, but the authorities insisted that it was a new type. By keeping the type designation “737”, with added designations to indicate that it was a variant, Boeing no doubt attracted customers. To introduce a new type, there must be an inventory kept for replacement parts for two different types of aircraft, maintenance facilities, training aids and procedures must be amended or added. It would add an enormous cost and the company would lose its special relationship with the manufacturer, which would have to be built again. Especially if Airbus would sell replacement aircraft to a Boeing operator.

Speaking from my personal experience, a rapid loss of cabin pressure – assuming that there are no further complications – is not the big deal people believe it is.

Usually, a cabin pressure warning comes on when the cabin altitude climbs above 10.500 feet, and masks will drop at 15.000.

We operated the Cessna 310 routinely at 9000 – 10.000 feet, 11.000 if ATC requested. And on one memorable flight from Berlin Schoenefeld to Moscow the Russian navigator that we had to carry insisted that we climb to 15.000, no pressurization, no oxygen. He told us: “You must climb to altitude faif tousant meters” (accent phonetically imitated), when we protested he said “You now climb to faif tousant meters or you see MIG…verry close.”. End of argument, we flew for about 2 hours at that altitude without ill effects.

I have had two rapid decompressions in the Citation, in both cases at high altitude (FL 370 and FL 390). It was no big drama. The second time we were just cleared to FL 90, so we just went down a bit more quickly than normal, we did not even declare an emergency.

Weird places I have seen articles related to this incident include:

A tech news site considering a phone which survived “the three-mile drop test”

My favorite financial column (paywall, sorry) rendering an opinion on this Reddit post (no paywall) asking if placing some immediate trades from inside the plane would have been illegal insider trading. (The columnist’s opinion is that it probably isn’t.)

A local advice column with tips on what to text your loved ones if this happens to your plane.

The thing that bugs me most about this is that emergency exits provide passenger safety; that someone at Boeing decided they could offer less safe aircraft for cheaper; and that some airlines decided to take them up on that offer for what I can only assume is a miniscule amount compared to the total cost of the aircraft.

I don’t think it’s that simple; somebody outside Boeing worked out how many exits were needed for a certain number of passengers, and Alaska Airlines decided it would rather give passengers a bit more room than jam in more people than that limit. (Seat pitch is a thing, although I don’t fly enough to know who allows more or less room between seats, let alone how much difference it makes to my comfort.) ISTR one of the links or clips above saying Boeing warned customers looking at this option that replacing the plug with a door after the aircraft was delivered would be expensive, but it’s not clear that Alaska was saving money in anything but the shortest term given the potential revenue loss from having fewer seats. (From the little I’ve seen recently, a lot of planes are 100% full when the doors close.)

On a different note: did anyone see anything in the links answering ColinTD’s question about how emergency doors are secured? The last time I looked at emergency-door instructions (quite a while ago, once airlines figured out that the added pitch of door rows was surchargeable), they did show that the door had to be pulled inward and rotated on two axes (so a short side was vertical and pointed outward) before it could fit through the opening. Has anyone looked at such directions recently? I can see that not making the door a wedge would make opening it faster….

On a newer 737, for the overwing exits you pull a handle at the top, and then the door swings outward on a hinge at the top.

The mid-cabin exits swing down and out.

More doors are more safety, that’s also true on low-density operations. However, the problem with installing these on lower-density operations is actually red tape. The smaller overwing exits are rated III, the main cabin doors are rated I, and these mid-cabin exits are rated II. That means they’re bigger than the overwing exits, but also this category needs more access space inside the aircraft than type III exits. So if an airline doesn’t want to provide that big space, they can’t have a type II exit there. The solution would be to downrate that exit to type III, but that’s not possible because type III emergency exits can only cover up to 70 seats in total, and the overwing exits already cover 65 seats.

So the airlines seem to not be allowed to fly their aircraft with this door installed even if it is not required when the access requirements are not met, which impacts the seating severely. It feels quite unfortunate.

An anonymous Boeing insider has provided some details, currently unverified.

https://viewfromthewing.com/boeing-whistleblower-production-line-has-enormous-volume-of-defects-bolts-on-max-9-werent-installed/

Apparently Spirit Aerosystems (no relation to the airline) do their warranty work right inside the Boeing factory in Renton, and when they have to remove the door plug, they have no way to enter that into the official tracking system that should’ve tracked the 4 door bolts and triggered an inspection when they were done—these warranty repairs are essentially done “off the books”, or so the commenters claim. I doubt the FAA will be pleased about that if these claims turn out to be true.

At this point, they might as well rename it the MAXident.

NBC news quoting the NTSB reported

that NO bolts were fitted to the door!

No doubt more information to follow, Chris

Yes, prelims report says they were removed to allow plug removal when fixing rivets at the factory, and then never put back before shipping the plane to alaska… https://www.ntsb.gov/investigations/Pages/DCA24MA063.aspx

They are still investigating what paperwork was in place to authorise the temoval and replacement steps.

My favorite quote from the preliminary report: “The separation of the MED plug from the airplane adversely affected the pressurization performance of the airplane”. The report has 19 pages and is quite detailed, including the event timeline; it’s a good read.

The NTSB confirmed the narrative of the anonymous whistleblower inasfar 5 rivets were replaced, and the door plug opened to do so, and the bolts not installed afterwards; they did not confirm the claim that the door seal was replaced.

Another issue that looks bad for Boeing: “The flight crew reported that the cockpit door had opened during the depressurization event. In a revision to the Flight Crew Operations Manual, issued on January 15, 2024, Boeing confirmed that the door functioned as designed.” This means it wasn’t in the manual before, which is kinda the same problem we saw with MCAS.

I do not understand why you’d make a door plug that isn’t intended to be removed frequently, and not make it, well, a plug design. Having worked on aircraft with plug design emergency exits, they were perfectly easy to pull for maintenance purposes; this one seems not to have been intended to be removed at all, but bizarrely designed to be easily-removable. And then the lack of bolt traceability…. Whole thing was an accident waiting to happen.