Rotation Gone Wrong: The Critical Error Behind LATAM’s Milan Tail Strike

On the 9th of July 2024, flight LA8073, operated by the Chilean airline LATAM, departed from Milano Malpensa for a passenger flight to São Paulo, Brazil. However, during the take-off run the “back end suddenly dropped after an apparent malfunction”, as Italian newspaper Corriere delle Serra described it.

I still can’t watch the video without wincing.

I wrote about the incident in August and explained about take-off data.

There are a number of tail strike incidents caused by the take-off weight being logged as lower than it actually was. This affects the take-off performance calculation, as the airspeed required for take-off is lower if the aircraft is lighter. The Pilot Flying gently applies back pressure on the control column, pitching the aircraft nose up to transition from rolling on the ground to flying in the air. This transition of lifting off is called rotation. However, if the take-off performance calculation is off, the heavier aircraft cannot achieve sufficient lift at that speed to safely rotate, and the tail strikes the ground as the aircraft struggles to take off.

[…]

There are many checks and balances which should catch a slip like this, as the wrong weight has serious consequences: not just that the airspeed is too high or low for rotation, but that all of the V-speeds are off, which affects go/no-go decisions.

Last week, the Italian aviation safety board, Agenzia Nazionale per la Sicureza del Volo (ANSV), released their preliminary report on the incident and confirmed that yes, the aircraft’s take-off data was wrong.

The first page is all the basic details that we mostly knew: the aircraft was a Boeing 777 (registered in Brazil as PT-MUG) operated by Tam Linhas Aereas for a passenger flight from Milan Malpensa (MXP) to São Paulo. The description of the event clearly represents what was understood at the time:

During the takeoff from RWY35L, the aircraft suffered a tail strike after the

rotation. The crew requested to enter a hold near MXP to carry out the NNC

procedures and returned to land in MXP.

The Boeing 777 is listed as having only minor damage. The runway came out worst, with a 720-metre scrape, about 2,350 feet, two metres left of the centre line.

But now we get to look at the load sheet.

Zero Fuel Weight: 219,460 kg

Take-off Weight: 328,425 kg

Fuel in Tanks: 109,625 kg

There were 15 crew, three pilots and twelve cabin crew. They took 122,702 litres of Jet-Fuel A-1 at Malpensa. Then 383 passengers boarded for the flight, making for a total of 398 people on board.

On the flight deck, an instructor pilot sat in the right seat and was Pilot Flying for the first leg. In the left seat was a captain-in-training who was the Pilot Monitoring. In the jumpseat was a relief captain.

The reference for take-off in the Flight Management System showed:

- Flaps 5°

- Thrust 56°

- V1: 145 kt

- VR: 149 kt

- V2: 156 kt

V-speeds are used to define the relative speeds which are important to the operation of the aircraft. These V-speeds need to be calculated for every flight. The key take-off speeds are V1, V2 and VR .

V1 is known as the decision speed, because the Pilot Flying has a go/no-go decision to make. Once the aircraft exceeds this speed, the take-off can no longer safely be aborted.

VR is the rotation speed: the speed at which the Pilot Flying pitches up slightly to bring the nose wheel up and cause the aircraft to “unstick” and climb away.

V2 is the take-off safety speed: the minimum speed that needs to be maintained in the event of an engine failure after V1 As long as the aircraft is travelling faster than V2, the aircraft should be able to climb away safely.

When the accident happened, I wrote:

Generally, the sequence is pretty simple. The crew gives the final fuel figures to the load controller. The load controller also verifies whether all planned passengers are accounted for and receives the final baggage and cargo weights from the airline staff. The loadsheet is then generated from this information and passed to the flight crew. The captain checks the loadsheet and signs it. The captain then enters the information into his or her Electronic Flight Bag and reads the data aloud so that the first officer can confirm the data and also program it into his or her own Electronic Flight Bag, as well as the Flight Management System. Then the two pilots will crosscheck the take-off performance calculation, including the take-off reference speeds.

I make it three specific checks where someone should notice if the weights or speeds are not as expected.

And that doesn’t even take into account three pilots instead of two. But — we guessed it right — these figures entered into the Flight Management System were wrong.

The flight crew had the full runway available to them, with a take-off distance available of 3,974 metres, which was luckily ample despite the circumstances.

The flight data recorder shows the following:

Directly before take-off, the gross weight was 328.2 tons with 109,100 kg of fuel on board.

The Boeing 777 began its take-off run at 11:25:59.

About 40 seconds later, when the aircraft was travelling 153 knots, a pitch-up command was recorded. Five seconds later, at 166 knots and a pitch of 8.2°, tail strike indicators 1 and 2 were activated.

The cockpit voice recorder recorded the sounds of the tail strike warning, followed by the tower controller warning the crew that they’d had a tail strike.

The furrow on the runway was 723 metres long and up to 6 centimetres (2 ⅓ inches) deep.

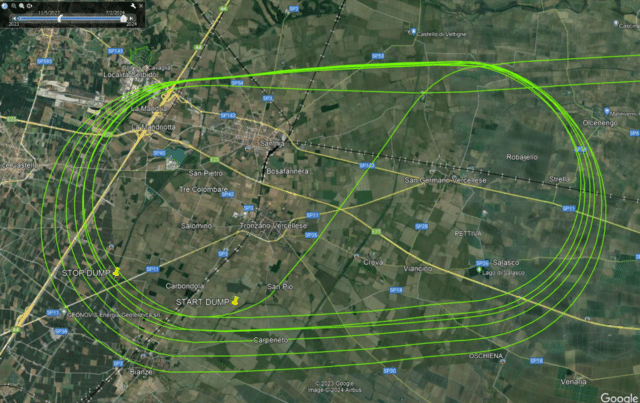

The Boeing 777 became airborne at 180 knots. The crew quickly requested to proceed towards the INLER waypoint, where they would enter a holding pattern at 6,000 feet.

Four minutes later, they declared PAN, PAN, PAN. A pan-pan call is a step down from MAYDAY: an urgent situation with no immediate risk to the aircraft or those on boards. Like MAYDAY (venez m’aider meaning come to my aid) , pan-pan comes from the French (panne meaning a breakdown).

At 11:40, 15 minutes from take-off and 8 minutes from their pan-pan call, the crew reported that they were going to need to dump fuel. The air traffic controller asked them to move their holding pattern further to the west. A few minutes later, the controller called again to say they’d found some parts of aircraft on the runway.

It took about half an hour to dump the fuel from the holding pattern at 6,000 feet, dropping the fuel weight from 103,700 kg to 31,600 kg. The reason they are at 6,000 feet is to ensure that the fuel doesn’t contaminate the ground below. Jet fuel is highly volatile and evaporates quickly into vapours which has a limited effect, whereas if the liquid fuel reaches the ground, it can contaminate water and poison crops.

After the flight crew had dumped 72,000 kg of fuel, they returned to the airport where they performed an ILS approach and landed normally on the parallel runway.

The tail skid, a drain mast and the tail strike sensor had all suffered damage in the prolonged tail strike.

And finally, the key point.

As a reminder, the take-off references entered into the Flight Management System by the flight crew were:

- Flaps 5°

- Thrust 56°

- V1: 145 kt

- VR: 149 kt

- V2: 156 kt

However, when the operator did the calculations after the fact, using the same details (Take-off weight of 328,425 kg, Runway 35L, outside ambient temperature of 30°), they found the take-off reference numbers to be quite a bit different.

- Flaps 5°

- Thrust 38°

- V1: 173 kt

- VR: 181 kt

- V2: 186 kt

Somehow, between three pilots, of which two were captains and one was training to become one, no one had noticed a discrepancy of over 30 knots for a safe take-off.

You can see all the facts and figures here: Serious incident – ARC: Abnormal runway contact – ANSV-24-0315

Now the task before the Agenzia Nazionale per la Sicurezza del Volo is a bit more complicated: How on earth did this happen and how do we stop it from happening again?

What are the “Thrust 56°” and “Thrust 38°” about?

Is it to do with this thing about telling the engines the outside temperature is higher to get de-rated thrust for the take off run which I’ve never got my head round? Can anybody explain?

I don’t know the meaning of those terms, but I can answer a piece of the 2nd question because I’ve been bitten by it. What we were told after missing our slot on an unexpectedly warm day was that the engines could be run at something above 100% of rating IFF the outside temperature was low enough; it wasn’t going to be low enough by the time of our new slot (>2 hours later — this was Gatwick, which has very limited capacity compared to demand), which meant they had to beg people to get off the plane, then search for their luggage to get it off, in order to get down to a weight that engines at 100% could get off the runway in a safe distance.

It does look like they managed to take off at well below the speed that was later calculated to be necessary (although they rotated at a higher speed than the incorrect calculations said was necessary). What I’m not following is why they over-rotated; did they just keep raising the nose when they didn’t start to rise as expected? Is that standard procedure? (Or possibly procedure encouraged at most modern airports for noise abatement — I remember how gently we climbed the one time my flight out of BOS took off over the ocean.) Does even a plane that complex and large have no indicator of the steepest safe angle when in contact with the ground?

Why is V1 higher when the plane is heavier? If that’s the no-abort speed, I’d expect it to be lower when the plane is heavier, as engine braking would be less effective.

What takeoff weight do the incorrect numbers entered in the FMS correspond to? That might indicate where the mistake was, e.g. using the empty weight rather than the zero-fuel weight.

What is the zero-fuel weight, and how is it calculated? Most commercial flights land with a substantial amount of fuel remaining due to a requirement for reserves in case problems at the intended destination prevent a landing; if the reported departure weight was the weight with people/luggage/cargo/… plus the fuel added at that stop, how did they allow for fuel remaining after the previous flight? (It can’t have been dumped; aside from the economics, there’s no place for it to go — letting it loose would be polluting (cf your note about how high they had to be to stop dumping) and it can’t go back in the storage tanks because it’s no longer pure.)

Nit: ISTM the weight at takeoff was 328 tonnes (“metric tons”), not 328 tons. Or have the names merged when I wasn’t watching? (I haven’t paid much attention to unit nomenclature since leaving chemistry 45 years ago.)

V1 also has another meaning:

So in practice, there’s usually a range of speeds where the aircraft can either stop safely or take off safely with one engine out. The airline can pick one in their operations manual. Picking the lowest speed makes sense because a) it’s usually better to take off than to risk a runway overrun/brake fire/etc, b) it gives the pilots some wiggle room if they’re slightly late in actioning their stop.

I’d call 180 kts (actual) vs. 181 kts (computed) as within the margin of error.

The cockpit goes up on rotation because it’s so far in front, even when the main gear is still on the ground. I imagine it’s hard to notice when the aircraft actually lifts off (or doesn’t).

Generally, the pilot would be focused on rotating at about 3⁰ per second, which ensures a safe lift-off when Vr is correct; the rotation continues after lift-off until the aircraft has reached the proper attitude for the climb. The advice is for the pilot to look outside to orient themselves to the pitch rate; they wouldn’t look at the artificial horizon in that phase of flight. Also, due to inertia, they couldn’t stop the rotation quickly anyway; but if they rotated more slowly in fear of a tailstrike, they’d lift off later and risk a runway overrun or contact with the runway lighting or other obstacles.

Some of the long Airbus jets have tailstrike protection that uses the radio altimeter and the pitch (which presumably works well as long as the runway is reasonably level), but they’re fly-by-wire, so the avionics can more easily correct the pilot.

Using the zero-fuel weight in place of the total weight seems to be a common mistake.